Stainless Steel Lashing Wire Market Growth CAGR Overview

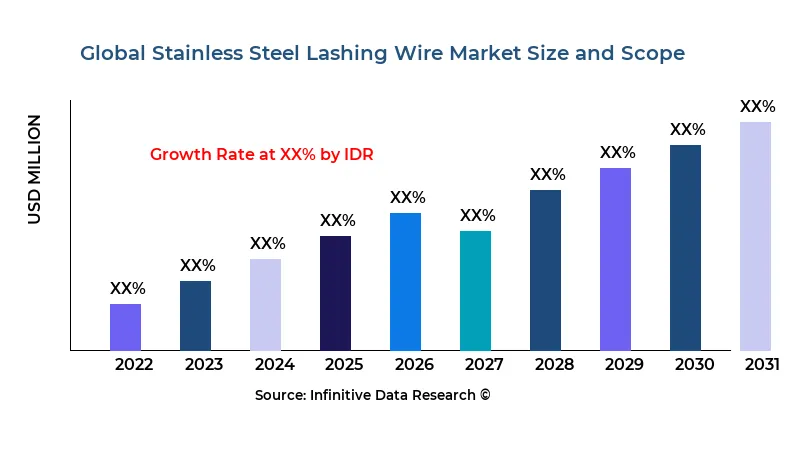

According to research by Infinitive Data Research, the global Stainless Steel Lashing Wire Market size was valued at USD 3.1 Bln (billion) in 2024 and is Calculated to reach USD 3.9 Bln (billion) by the end of 2032, growing at an anticipated compound annual growth rate (CAGR) of 7.6% during the forecast period 2024 to 2032. This projected growth is driven by its increasing adoption across Chemical & Materials industries such as Telecommunications, Utilities cable TV Industries, OtherIn recent years, the stainless steel lashing wire market has been propelled by the surge in global logistics and shipping activities. As containerization becomes ever more prevalent in trade, demand for durable, corrosion‑resistant lashing solutions has risen sharply. Manufacturers are investing in high‑precision drawing and annealing processes to deliver wires that meet stringent tensile and elongation requirements. This evolution is reshaping the competitive landscape, as producers with advanced metallurgical capabilities secure long‑term supply contracts with major shipping lines and freight forwarders.

Simultaneously, end‑users in construction, renewable energy and manufacturing are adopting stainless steel lashing wire for securing heavy loads, scaffolding and PV modules. The versatility of grades such as 304 and 316—offering superior tensile strength and salt‑spray resistance—has expanded application scopes into offshore and marine environments. These shifting end‑use patterns are prompting suppliers to diversify product lines, offering pre‑cut lengths, custom coatings and welded fittings. Companies that can pair material expertise with tailored service solutions are gaining market share at the expense of undifferentiated commodity suppliers.

Raw material volatility, particularly in nickel and chromium prices, is a critical dynamic underpinning the market. Fluctuations in alloying element costs have forced manufacturers to adopt hedging strategies, vertical integration and alternative alloy formulations. Those able to optimize melt chemistry without sacrificing performance are achieving margin resilience. At the same time, producers are collaborating with scrap collectors and alloy smelters to secure stable feedstock, thereby mitigating supply‑chain disruptions and ensuring consistent quality—key differentiators in an environment where product failure can incur massive liability.

Digitalization and automation are also reshaping production workflows. Leading mills are implementing Industry 4.0 solutions—real‑time process control, predictive maintenance and traceability systems—that enhance yield and guarantee batch consistency. These investments not only reduce operating costs but also drive faster time‑to‑market for new wire grades. As the industry transitions toward more data‑driven operations, suppliers with robust digital infrastructures are positioned to respond more nimbly to customer specifications and regulatory requirements, reinforcing their competitive advantage.

>>> Understand The Key Trends Shaping This Market:- Download PDF Sample

Stainless Steel Lashing Wire Market Growth Factors

Innovation in alloy design and processing drives sustained growth. Recent developments in duplex and super‑duplex stainless steels offer enhanced strength and corrosion resistance at competitive prices, opening new markets in offshore oil & gas and chemical processing. Producers that invest in pilot‑scale trials to validate these alloys in high‑stress lashing applications are capturing early market share. The ability to translate lab‑scale findings into commercial‑scale production has become a key growth driver, as specifiers demand both performance and cost efficiency.

Global infrastructure spending, especially on ports, bridges and renewable energy, underpins robust demand. Governments across Asia‑Pacific and the Middle East are financing large‑scale projects where wire lashing is critical for material handling and structural integrity. These macroeconomic trends feed directly into stainless steel wire consumption, as project engineers prioritize long‑life, low‑maintenance solutions. As a result, manufacturers with regional production footprints and local technical support services are capturing major infrastructure accounts.

Environmental regulations and sustainability goals are accelerating the shift from carbon‑steel to stainless steel in many lashing applications. Although stainless grades carry a higher upfront cost, their negligible maintenance requirements and recyclability over multiple life cycles yield lower total cost of ownership. Companies that can quantify and communicate these life‑cycle benefits are unlocking new opportunities, especially in markets where “green procurement” policies reward low‑carbon solutions. This trend is steadily broadening customer bases and stimulating growth.

Finally, the rise of e‑commerce and just‑in‑time inventory models is reshaping distribution strategies. Buyers now expect smaller, more frequent shipments of cut‑to‑length wire and fast turnaround on custom orders. Distributors that integrate digital ordering platforms with regional warehousing can offer enhanced service levels, reducing lead times by weeks. This shift toward agile supply chains is a potent growth catalyst, compelling traditional producers to evolve their distribution models or cede ground to more responsive competitors.

Market Analysis By Competitors

- Loos & Co.

- Power Manufacturing

- Phoenix Utility Products Corporation

- CWI-America

- Nevatia steel

- Wire World

- Multicom, Inc

- Anand Arc Ltd.

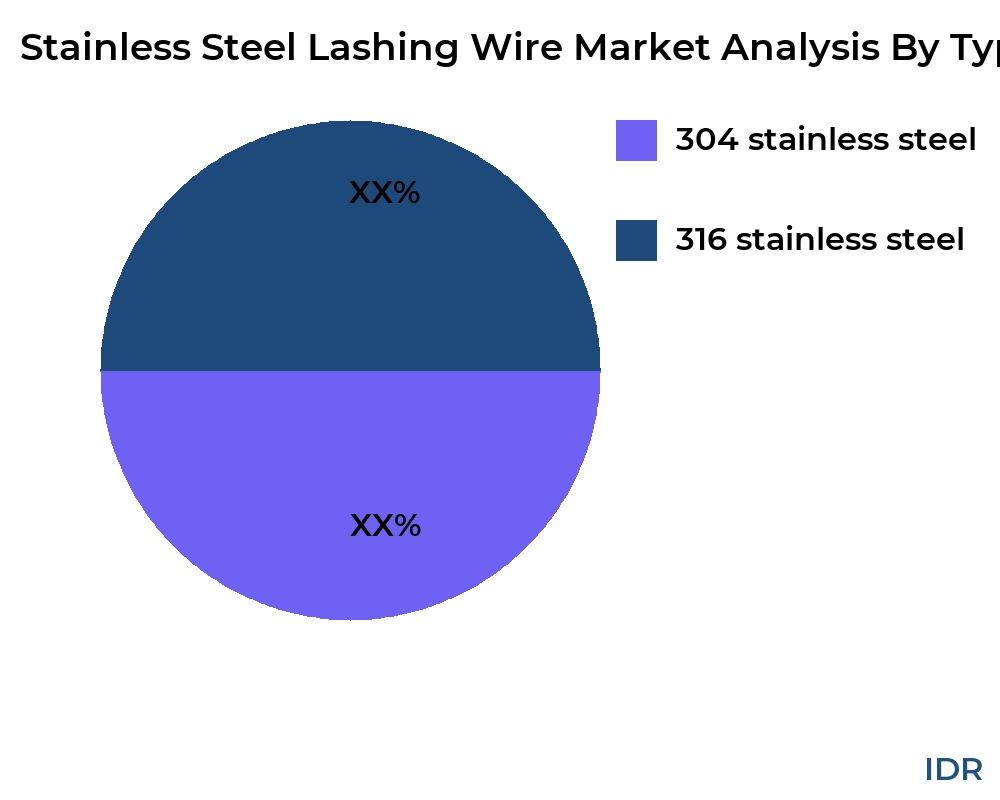

By Product Type

- 304 stainless steel

- 316 stainless steel

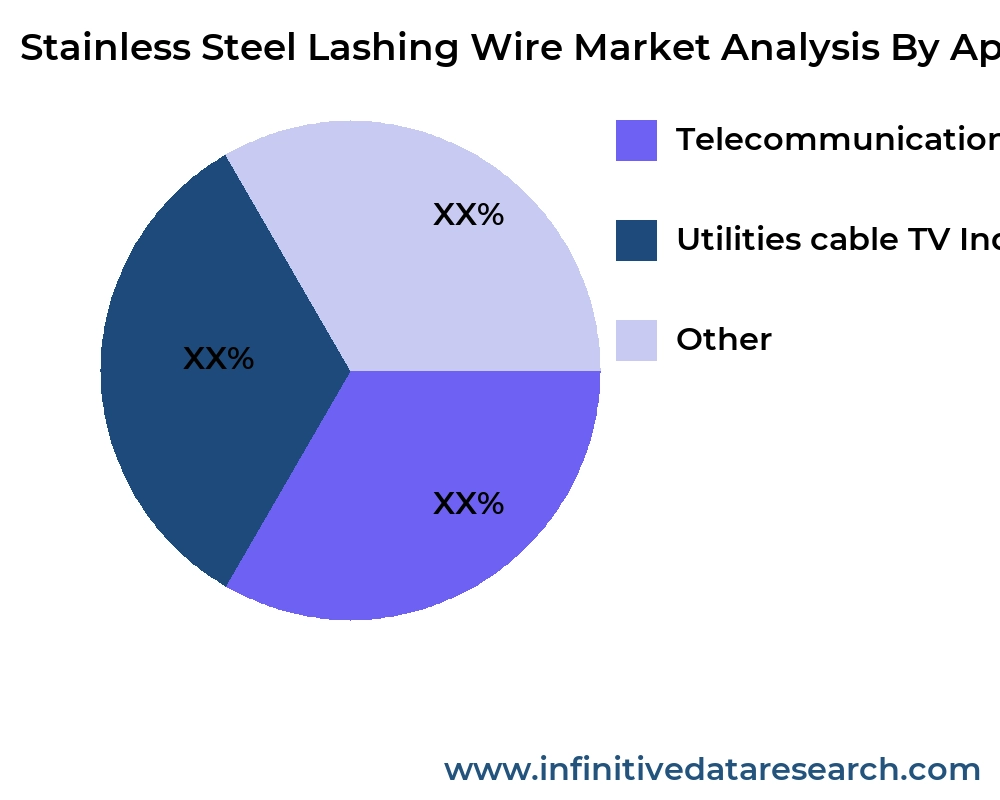

By Application

- Telecommunications

- Utilities cable TV Industries

- Other

>>> Understand The Key Trends Shaping This Market:- Understand The Key Trends Shaping This Market:-

Stainless Steel Lashing Wire Market Segment Analysis

Distribution Channel:

Distributors and trading houses remain the primary channels for stainless steel lashing wire, leveraging broad inventories and technical expertise to serve global shipping and construction clients. In developed markets, direct sales organizations—often embedded within major steel producers—provide tailored consultancy and on‑site support, securing large volume contracts. E‑commerce platforms are emerging, offering standardized cut‑lengths of common grades with next‑day delivery, appealing to smaller OEMs and regional installers. The interplay between digital portals, local warehouses and global producer networks defines the modern distribution ecosystem.

Compatibility:

Lashing wire must interface seamlessly with tensioners, turnbuckles and jointing fittings. Compatibility considerations extend to galvanic corrosion when stainless wire contacts carbon‑steel hardware, prompting demand for coated or insulated options. Vendors that supply matched accessory kits—complete with clamps, ferrules and protective sleeves—simplify installation and reduce corrosion risk. Additionally, compatibility with automated tensioning tools is gaining importance in large‑scale logistics operations, as it improves installation speed and ensures consistent preload.

Price:

Pricing is driven primarily by alloy composition and processing intensity. High‑nickel 316 grades command premiums, reflecting superior pitting resistance essential for marine use. Duplex grades, offering equivalent strength with lower nickel content, are gaining share by delivering cost savings without performance compromise. Bulk, uncoated wire is most cost‑effective for general industrial applications, while value‑added offerings—polished finishes, laser‑etched traceability codes—fetch higher margins. Price dynamics hinge on global stainless steel scrap availability and alloy surcharge mechanisms tied to commodity indices.

Product Type:

The market offers a spectrum of wire types: bright‐drawn cold‐worked, pickled and passivated, coated (PVC, PET) and duplex/super‑duplex formulations. Cold‑worked variants provide excellent fatigue resistance for dynamic tensioning. Coated wires deliver mechanical protection and identification colors. Duplex and super‑duplex wires suit extreme corrosion environments. Emerging high‑entropy alloys, though still niche, promise breakthroughs in both strength and corrosion performance. Product diversification allows suppliers to address specific end‑use requirements, from simple bundling tasks to critical offshore mooring applications.

| REPORT ATTRIBUTES | DETAILS |

|---|---|

| Study Period |

2019-2032 |

| Base Year |

2023 |

| Forecast Period |

2024-2032 |

| Historical Period |

2019-2022 |

| Unit |

Value (USD Billion) |

| Key Companies Profiled |

Loos & Co., Power Manufacturing, Phoenix Utility Products Corporation, CWI-America, Nevatia steel, Wire World, Multicom, Inc, Anand Arc Ltd. |

| Segments Covered |

By Product |

| Customization Scope |

Free report customization (equivalent to up to 3 analyst working days) with purchase. Addition or alteration to country, regional and segment scope |

>>> Overview of Market Analysis:- Download PDF Sample

Stainless Steel Lashing Wire Market Regional Analysis

North America leads in high‑specification applications, supported by a mature petrochemical and offshore sector. The U.S. Gulf Coast demand for duplex wire in subsea umbilical lashing and FPSO deck securing is particularly strong. Local mills invest heavily in certification (NACE, ASTM) to meet end‑user requirements. Distribution networks are dense, and service centers offer rapid cutting, inspection and packaging.

Europe is dominated by established stainless producers in Germany and Italy, supplying both domestic engineering firms and re‑export markets. The region’s rigorous environmental standards drive adoption of high‑grade weldable duplex wires in bridge construction and rail infrastructure. European suppliers benefit from integrated supply chains and proximity to major ports, facilitating efficient throughput to the Mediterranean and North Sea markets.

Asia‑Pacific is the fastest‑growing region, propelled by massive port expansions in China, India and Southeast Asia. Local stainless producers are scaling capacity and offering cost‑competitive 304 wire grades for general logistics. However, demand for duplex and 316 grades is rising as regional shipyards and offshore developments adopt higher performance standards. Regional distributors are expanding their footprints to capture this burgeoning demand.

Rest of World markets such as the Middle East and Latin America are increasingly sourcing duplex wire for oil & gas projects and renewable energy installations. While supplier options remain limited, major steelmakers are establishing toll‑processing and joint ventures to localize production. In Africa, a nascent demand for stainless lashing wire in mining and heavy infrastructure is emerging, spurred by new port and rail projects funded by international investors.

global Stainless Steel Lashing Wire market revenue (usd million) comparison by players 2024-2032

| Company/players | 2021 | 2022 | 2023 | 2024 | ... | (2032) |

|---|---|---|---|---|---|---|

| Loos & Co. | XX | XX | XX | XX | XX | XX |

| Power Manufacturing | XX | XX | XX | XX | XX | XX |

| Phoenix Utility Products Corporation | XX | XX | XX | XX | XX | XX |

| CWI-America | XX | XX | XX | XX | XX | XX |

| Nevatia steel | XX | XX | XX | XX | XX | XX |

| Wire World | XX | XX | XX | XX | XX | XX |

| Multicom, Inc | XX | XX | XX | XX | XX | XX |

| Anand Arc Ltd. | XX | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX | XX |

global Stainless Steel Lashing Wire market revenue (usd million) comparison by product type 2024-2032

Product Type

2023

2024

...

2032

CAGR%(2024-32)

304 stainless steel

XX

XX

XX

XX

XX

316 stainless steel

XX

XX

XX

XX

XX

Total

XX

XX

XX

XX

XX

| Product Type | 2023 | 2024 | ... | 2032 | CAGR%(2024-32) |

|---|---|---|---|---|---|

| 304 stainless steel | XX | XX | XX | XX | XX |

| 316 stainless steel | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX |

global Stainless Steel Lashing Wire market revenue (usd million) comparison by application 2024-2032

Application

2023

2024

...

2032

CAGR%(2024-32)

Telecommunications

XX

XX

XX

XX

XX

Utilities cable TV Industries

XX

XX

XX

XX

XX

Other

XX

XX

XX

XX

XX

Total

XX

XX

XX

XX

XX

| Application | 2023 | 2024 | ... | 2032 | CAGR%(2024-32) |

|---|---|---|---|---|---|

| Telecommunications | XX | XX | XX | XX | XX |

| Utilities cable TV Industries | XX | XX | XX | XX | XX |

| Other | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX |

>>> Market Understand Through Graph And Chart:- Download PDF Sample

Stainless Steel Lashing Wire Market Competitive Insights

The stainless steel lashing wire market is moderately consolidated, with Siemens‑backed billet producers and specialized wire mills commanding leadership through integrated melt‑to‑wire operations. Their scale enables investment in advanced metallurgical processes and expansive distribution networks. Mid‑tier players compete by offering rapid service, customization and regional closeness to end‑users. Niche specialists—focusing on bespoke alloys or coatings—thrive by addressing exacting marine, chemical and renewable energy specifications.

Innovation cycles are accelerating as companies seek differentiation. Duplex wire adoption is a case in point: initially a premium, niche product, it has rapidly mainstreamed due to improved dual‐phase microstructures and lower nickel formulations. Producers that swiftly retooled their mills to cold‐draw duplex grades have captured disproportionate share gains. Investment in pilot lines and external R&D partnerships remains key to staying ahead in alloy development.

Cost pressures from raw material volatility are forcing consolidation and strategic alliances. Several wire mills have entered alliances with scrap collectors and upstream smelters to secure stable feedstock at predictable costs. Joint ventures between stainless slab producers and wire‐drawing specialists streamline value chains and reduce transaction layers. These integrated models are reshaping competitive dynamics, privileging players with end‑to‑end control.

Service excellence is becoming a deciding factor as end‑users demand not just wire, but turnkey lashing solutions. Suppliers that bundle technical training, installation support and ongoing maintenance services create high‑value propositions. Digital customer portals offering traceability, order‑tracking and material certificates further differentiate leading suppliers. In a market where product failure carries safety and liability risks, these service capabilities underpin long‑term customer loyalty.

Stainless Steel Lashing Wire Market Competitors

United States

• Prysmian Group (U.S. Stainless Division)

• Carpenter Technology Corporation

• Allegheny Technologies Inc. (ATI)

• Welded Wire Products LLC

• Brady Wire Company

Germany

• VDM Metals GmbH

• ThyssenKrupp Steel Europe AG

• Friedr. Lohmann GmbH

• Kaiser Stainless Solutions

• Schmolz + Bickenbach AG

Japan

• JFE Steel Corporation

• Nippon Yakin Kogyo Co., Ltd.

• Daido Steel Co., Ltd.

• Kobe Steel, Ltd.

• Yoshino Steel Works

China

• Outokumpu (China)

• Angang Steel Company Limited

• Baosteel Special Steel Co.

• TISCO (Taiyuan Iron & Steel)

• Shagang Group

India

• Tata Steel Long Products

• Jindal Stainless Ltd.

• Aperam Stainless India

• ArcelorMittal Nippon Steel India

• Viraj Profiles

South Korea

• POSCO

• Dongkuk Steel Mill Co.

• SeAH Steel Corp.

• Hanwha Special Steel

• STX Stainless Steel

Stainless Steel Lashing Wire Market Top Competitors

1. Prysmian Group (U.S. Stainless Division)

Prysmian’s U.S. Stainless Division leverages the global leader’s scale in cable and wire manufacturing to dominate the stainless steel lashing segment. With vertically integrated facilities spanning smelting, rolling and cold drawing, Prysmian ensures stringent quality control from melt to finished wire. Its North American plants are certified to ASTM and NACE standards, catering to oil & gas, marine and construction clients. Prysmian’s extensive R&D investment yields proprietary alloy formulations and coating technologies that enhance corrosion resistance and fatigue life. A broad distribution network—including company‑owned warehouses and authorized partners—provides just‑in‑time service and technical support. Digital ordering portals and traceability platforms further strengthen customer engagement. The division’s focus on life‑cycle cost optimization and circular economy practices positions it as a market innovator and cost leader. Its strategic expansions in Mexico and Canada anticipate rising infrastructure spending across NAFTA corridors.

2. VDM Metals GmbH

VDM Metals, part of the Leifeld Group, is Europe’s premier supplier of high‑performance stainless alloys, including lashing wires. Its core competency lies in specialized alloy design—duplex, super‑duplex and nickel‑based grades—tailored for extreme corrosion environments. VDM’s modern wire‑drawing facilities in Germany and the U.S. employ advanced multi‑stage annealing to achieve superior mechanical properties. The company’s deep technical services team collaborates with OEMs on custom solutions, from mooring lines on FPSOs to securing solar panels in desert installations. VDM’s integrated quality management system ensures full material traceability and compliance with stringent industry certifications. Its proactive R&D pipeline explores high‑entropy and low‑carbon stainless formulations, anticipating future regulatory shifts. With a strong presence in Europe, North America and Asia, VDM garners premium pricing through technological leadership and unparalleled alloy expertise.

3. JFE Steel Corporation

JFE Steel, a leading Japanese steelmaker, commands significant share in Asia‑Pacific for stainless lashing wire. The company’s proprietary electric arc furnace technology and scrap blending expertise yield cost‑effective, low‑impurity stainless grades. JFE’s advanced cold‑drawing lines produce wire with excellent surface finish and consistent mechanical performance, critical for high‑precision lashing applications. The firm’s strategic JV with POSCO extends its reach into Southeast Asian markets, where infrastructure projects drive volume demand. JFE’s robust domestic distribution network, supported by localized packaging and coating services, ensures rapid delivery to shipyards and logistics hubs. The company continuously refines its alloy recipes to reduce nickel content without sacrificing corrosion resistance, addressing both cost and environmental pressures. JFE’s commitment to sustainability is evidenced by its carbon‑neutral stainless roadmap, appealing to environmentally conscious end‑users.

4. Carpenter Technology Corporation

Carpenter Technology is renowned in the U.S. for ultra‑high‑grade stainless and specialty alloy wires used in critical aerospace and defense lashing applications. Its clean‑steel processes—vacuum induction melting, electro‑slag remelting—produce wire with exceptional purity and mechanical consistency. Carpenter’s in‑house metallurgical labs accelerate alloy development, enabling rapid commercialization of new grades with enhanced fatigue life. The company’s global service centers offer precision cutting, marker banding and weldability testing, catering to stringent OEM specifications. Carpenter’s supply agreements with major aircraft and marine engine manufacturers underscore its reputation for reliability. Its high‑value focus and rigorous quality systems—AS9100, ISO 9001—command premium positioning in the market.

5. Outokumpu

Outokumpu, the Finnish stainless steel giant, leverages its global melt‑shop network to supply a broad portfolio of lashing wire grades. With integrated recycling capabilities and a strong raw material sourcing strategy, Outokumpu maintains stable pricing despite alloy surcharge volatility. Its cold‑drawing plants in Europe and the Americas offer customizable surface finishes—bright, galvanized and coated—meeting diverse end‑use demands. Outokumpu’s “Digital Wire” initiative integrates RFID tagging and blockchain traceability, enhancing supply‑chain transparency. The company’s strong presence in marine and chemical sectors is supported by deep corrosion‑testing expertise, ensuring product fitness in harsh environments. Outokumpu’s sustainability credentials—high scrap utilization, low CO₂ footprint—resonate with green procurement policies, bolstering its market leadership.

6. Lincoln Electric

Lincoln Electric, a U.S. welding equipment leader, has extended into MIG and TIG wire production to provide turnkey welding solutions. Its stainless steel consumables division benefits from synergies with arc‑welding expertise, offering wires specifically engineered for optimal burn‑off rates and deposition efficiency. Lincoln’s global distribution of welding wires ensures ready availability for infrastructure, shipbuilding and automotive sectors. The company invests in joint R&D with OEMs to tailor wire chemistries for robotic welding applications, enhancing process reliability. Lincoln’s strong brand and comprehensive service network—training, application engineering—differentiate its wire offerings as part of integrated welding packages. Its focus on performance consistency and user support secures loyalty among welding contractors and industrial fabricators.

7. ESAB

ESAB, a Swedish‑origin welding and cutting specialist, offers an extensive range of MIG and TIG stainless wires across multiple grades and diameters. Its global supply footprint, with manufacturing sites in Europe, North America and Asia, ensures localized production and rapid order fulfillment. ESAB’s wires are engineered for low spatter and smooth arc characteristics, catering to automated and manual welding alike. The company’s proprietary flux‑core wire technologies enhance deposition rates, reducing overall welding costs. ESAB supports customers with 24/7 technical hotlines and on‑site application trials, reinforcing its position as a full‑service provider. Its commitment to sustainability is evident in recyclable spools and reduced packaging waste initiatives.

8. Bohler Welding (voestalpine AG)

Böhler, under voestalpine AG, supplies premium TIG and MIG wires renowned for superior mechanical properties and corrosion resistance. Its R&D centers in Austria pioneer new alloy recipes—low‑heat input, high‑strength wires—that address evolving welding challenges in energy and marine sectors. Böhler’s consistent wire chemistry and tight tolerances are critical for automated robotic welding cells in the automotive industry. The company’s global distribution network—centered in Europe, North America and Asia—offers technical training and weld procedure qualification services. Böhler’s emphasis on alloy traceability and certification has earned it preferred status among critical infrastructure fabricators.

9. Fronius International

Fronius, an Austrian innovator in welding technology, complements its arc‑welding power sources with a dedicated line of high‑performance stainless welding wires. Its synergistic approach integrates wire chemistry with machine waveform optimization to deliver superior weld quality and reduced rework. Fronius global centers provide hands‑on workshops and weld process consulting, ensuring users extract maximum value from matched equipment‑wire systems. The company’s commitment to digital welding—featuring real‑time monitoring of wire feed and arc stability—further differentiates its offering. Fronius’s reputation for reliability and innovation secures its position among top-tier fabricators requiring zero‑defect performance.

10. Sandvik Materials Technology

Sandvik’s stainless and nickel alloy wire division is a leader in premium lashing and welding wire solutions. Its expertise in powder metallurgy and precision cold drawing yields wires with exceptional homogeneity and fatigue resistance. Sandvik services critical industries—aerospace, medical, energy—where wire performance can be safety‑critical. The company’s global test laboratories validate wire behavior under extreme conditions, from cryogenic temperatures to high heat flux. Sandvik’s integrated supply chain, spanning ore mining to finished wire, ensures stable alloy availability and supply continuity. Its strong focus on R&D and process innovation underpins its leadership in next‑generation alloy wires.

The report provides a detailed analysis of the Stainless Steel Lashing Wire market across various regions, highlighting the unique market dynamics and growth opportunities in each region.

- US

- Canada

- Mexico

- UK

- Germany

- France

- Italy

- Russia

- Spain

- Switzerland

- Austria

- Belgium

- Rest of Europe

- China

- Japan

- South Korea

- Indonesia

- Vietnam

- Philippines

- Australia

- Thailand

- Singapore

- Rest of APAC

- UAE

- Saudi Arabia

- Egypt

- South Africa

- Israel

- Rest of MEA

- Brazil

- Argentina

- Rest of Latin America

>>> Need A Different Region Or Segment? Download PDF Sample

Key Takeaways

- The global Stainless Steel Lashing Wire market is expected to grow significantly from 2024 to 2032, driven by technological advancements, increasing demand, and government investments in urbanization.

- The market is characterized by a diverse range of manufacturers, product types, and applications, catering to different consumer needs and preferences.

- Regional insights highlight the unique market dynamics and growth opportunities in various regions, including North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

- The competitive landscape features key players who have created a dynamic and diverse market environment through collaborations, mergers and acquisitions, and innovative product developments.

- Market trends such as technological advancements, sustainability, customization, and digital transformation are shaping the growth and development of the Stainless Steel Lashing Wire market.

- Despite the positive outlook, the market faces challenges such as regulatory compliance, high initial investment costs, and economic uncertainties.

- The report provides comprehensive coverage of market size, market share, growth factors, and strategic insights to help businesses navigate the dynamic Stainless Steel Lashing Wire market and achieve long-term success.

By leveraging the information provided in this report, businesses can develop effective strategies, address market challenges, and capitalize on growth opportunities to ensure sustainable growth and long-term success in the global Stainless Steel Lashing Wire market.

- Introduction

- Objectives of the Study

- Market Definition

- Research Scope

- Currency

- Key Target Audience

- Research Methodology and Assumptions

- Executive Summary

- Premium Insights

- Porter’s Five Forces Analysis

- Value Chain Analysis

- Top Investment Pockets

- Industry Trends

- Market Dynamics

- Market Evaluation

- Drivers

- Restraints

- Opportunities

- Challenges

- Global Stainless Steel Lashing Wire Market Analysis and Projection, By Companies

- Segment Overview

- Loos & Co.

- Power Manufacturing

- Phoenix Utility Products Corporation

- CWI-America

- Nevatia steel

- Wire World

- Multicom, Inc

- Anand Arc Ltd.

- Global Stainless Steel Lashing Wire Market Analysis and Projection, By Type

- Segment Overview

- 304 stainless steel

- 316 stainless steel

- Global Stainless Steel Lashing Wire Market Analysis and Projection, By Application

- Segment Overview

- Telecommunications

- Utilities cable TV Industries

- Other

- Global Stainless Steel Lashing Wire Market Analysis and Projection, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Russia

- Spain

- Switzerland

- Austria

- Belgium

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Vietnam

- Philippines

- Australia

- Thailand

- Singapore

- Rest of APAC

- Middle East

- UAE

- Saudi Arabia

- Egypt

- South Africa

- Israel

- Rest of MEA

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Global Stainless Steel Lashing Wire Market-Competitive Landscape

- Overview

- Market Share of Key Players in the Stainless Steel Lashing Wire Market

- Global Company Market Share

- North America Company Market Share

- Europe Company Market Share

- APAC Company Market Share

- Competitive Situations and Trends

- Coverage Launches and Developments

- Partnerships, Collaborations, and Agreements

- Mergers & Acquisitions

- Expansions

- Company Profiles

- Loos & Co.

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Power Manufacturing

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Phoenix Utility Products Corporation

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- CWI-America

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Nevatia steel

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Wire World

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Multicom, Inc

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Anand Arc Ltd.

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

List of Table

- Drivers of Global Stainless Steel Lashing Wire Market: Impact Analysis

- Restraints of Global Stainless Steel Lashing Wire Market: Impact Analysis

- Global Stainless Steel Lashing Wire Market, By Technology, 2023-2032(USD Billion)

- global 304 stainless steel, Stainless Steel Lashing Wire Market, By Region, 2023-2032(USD Billion)

- global 316 stainless steel, Stainless Steel Lashing Wire Market, By Region, 2023-2032(USD Billion)

- global Telecommunications, Stainless Steel Lashing Wire Market, By Region, 2023-2032(USD Billion)

- global Utilities cable TV Industries, Stainless Steel Lashing Wire Market, By Region, 2023-2032(USD Billion)

- global Other, Stainless Steel Lashing Wire Market, By Region, 2023-2032(USD Billion)

List of Figures

- Global Stainless Steel Lashing Wire Market Segmentation

- Stainless Steel Lashing Wire Market: Research Methodology

- Market Size Estimation Methodology: Bottom-Up Approach

- Market Size Estimation Methodology: Top-down Approach

- Data Triangulation

- Porter’s Five Forces Analysis

- Value Chain Analysis

- Top investment pocket in the Stainless Steel Lashing Wire Market

- Top Winning Strategies, 2023-2032

- Top Winning Strategies, By Development, 2023-2032(%)

- Top Winning Strategies, By Company, 2023-2032

- Moderate Bargaining power of Buyers

- Moderate Bargaining power of Suppliers

- Moderate Bargaining power of New Entrants

- Low threat of Substitution

- High Competitive Rivalry

- Restraint and Drivers: Stainless Steel Lashing Wire Market

- Stainless Steel Lashing Wire Market Segmentation, By Technology

- Stainless Steel Lashing Wire Market For Live Attenuated, By Region, 2023-2033 ($ Billion)

- Global Stainless Steel Lashing Wire Market, By Technology, 2023-2032(USD Billion)

- global 304 stainless steel, Stainless Steel Lashing Wire Market, By Region, 2023-2032(USD Billion)

- global 316 stainless steel, Stainless Steel Lashing Wire Market, By Region, 2023-2032(USD Billion)

- global Telecommunications, Stainless Steel Lashing Wire Market, By Region, 2023-2032(USD Billion)

- global Utilities cable TV Industries, Stainless Steel Lashing Wire Market, By Region, 2023-2032(USD Billion)

- global Other, Stainless Steel Lashing Wire Market, By Region, 2023-2032(USD Billion)

- Loos & Co.: Net Sales, 2023-2033 ($ Billion)

- Loos & Co.: Revenue Share, By Segment, 2023 (%)

- Loos & Co.: Revenue Share, By Region, 2023 (%)

- Power Manufacturing: Net Sales, 2023-2033 ($ Billion)

- Power Manufacturing: Revenue Share, By Segment, 2023 (%)

- Power Manufacturing: Revenue Share, By Region, 2023 (%)

- Phoenix Utility Products Corporation: Net Sales, 2023-2033 ($ Billion)

- Phoenix Utility Products Corporation: Revenue Share, By Segment, 2023 (%)

- Phoenix Utility Products Corporation: Revenue Share, By Region, 2023 (%)

- CWI-America: Net Sales, 2023-2033 ($ Billion)

- CWI-America: Revenue Share, By Segment, 2023 (%)

- CWI-America: Revenue Share, By Region, 2023 (%)

- Nevatia steel: Net Sales, 2023-2033 ($ Billion)

- Nevatia steel: Revenue Share, By Segment, 2023 (%)

- Nevatia steel: Revenue Share, By Region, 2023 (%)

- Wire World: Net Sales, 2023-2033 ($ Billion)

- Wire World: Revenue Share, By Segment, 2023 (%)

- Wire World: Revenue Share, By Region, 2023 (%)

- Multicom, Inc: Net Sales, 2023-2033 ($ Billion)

- Multicom, Inc: Revenue Share, By Segment, 2023 (%)

- Multicom, Inc: Revenue Share, By Region, 2023 (%)

- Anand Arc Ltd.: Net Sales, 2023-2033 ($ Billion)

- Anand Arc Ltd.: Revenue Share, By Segment, 2023 (%)

- Anand Arc Ltd.: Revenue Share, By Region, 2023 (%)

Infinitive Data Research provides comprehensive market research, offering in-depth market analysis to help companies understand their target market and industry competition. This research predicts the market acceptance of your brand and products, ensuring informed decision-making for business success.

Competitor Analysis in the Stainless Steel Lashing Wire Industry

Conducting a competitor analysis involves identifying competitors within the Stainless Steel Lashing Wire industry and studying their various marketing strategies. This comparative data allows you to assess your company's strengths and weaknesses relative to competitors, providing insights to enhance your market position.

Importance of Continuous Market Research

Consistently conducting market research is essential for minimizing risk at every stage of business operations. Stainless Steel Lashing Wire market research enables you to collect qualitative and quantitative data, which, when properly analyzed, leads to wise decisions that align with user and customer needs. Below are some crucial lessons learned through the Stainless Steel Lashing Wire market research process:

Key Dimensions of Stainless Steel Lashing Wire Market Analysis

- Trend and Pattern Identification: Analyzing data to spot market trends and patterns.

- Pricing Analysis: Assessing keyword pricing strategies.

- Actionable Insights: Implementing insights derived from data analysis.

- Market Potential: Evaluating the potential of the Stainless Steel Lashing Wire market.

- Competitor Analysis: Studying competitors' strategies and performance.

- Location Analysis: Assessing optimal locations for market penetration.

- Distribution Channels Analysis: Evaluating the effectiveness of distribution channels.

- Market Size and Growth Rate: Measuring market size and growth potential.

- Market Profitability: Assessing profitability prospects.

- Key Success Factors: Identifying critical factors for success.

- Cost Structure: Understanding the cost structure within the Stainless Steel Lashing Wire industry.

Target Audience for the Report

This report is valuable for a diverse audience, including:

- Stainless Steel Lashing Wire Market Manufacturers: To understand market dynamics and enhance production strategies.

- Investors and Financing Companies: To assess investment opportunities and risks.

- Stainless Steel Lashing Wire Market Suppliers: To identify market demands and supply chain efficiencies.

Necessity of the Report

Making Crucial Business Decisions

Understanding the Stainless Steel Lashing Wire market, competition, and industry landscape is vital for making informed business decisions. Without current and relevant market research, decisions may be based on outdated or irrelevant information, potentially harming the business.

Securing Investment Funds

Attracting investors requires demonstrating thorough market research. Investors need assurance that you understand the sector, current and potential competition, and whether your idea addresses a market need.

Identifying New Business Opportunities

Stainless Steel Lashing Wire market research goes beyond understanding trends and consumer behavior. It identifies new revenue streams and opportunities for business pivots. These insights can lead to strategic changes in the business model, promoting growth and adapting to market challenges.

Avoiding Business Failures

Market research also plays a crucial role in risk mitigation. It can reveal when not to pursue certain actions, saving the company from potential losses in revenue, brand image, and more. This proactive approach is often overlooked but is essential for long-term success.

Conclusion

Infinitive Data Research's comprehensive Stainless Steel Lashing Wire market research provides critical insights for making solid business decisions, securing investments, identifying new opportunities, and avoiding potential failures. Understanding market dynamics through continuous research ensures your company remains competitive and thrives in the Stainless Steel Lashing Wire industry.