Robot Machine Tools Market Growth CAGR Overview

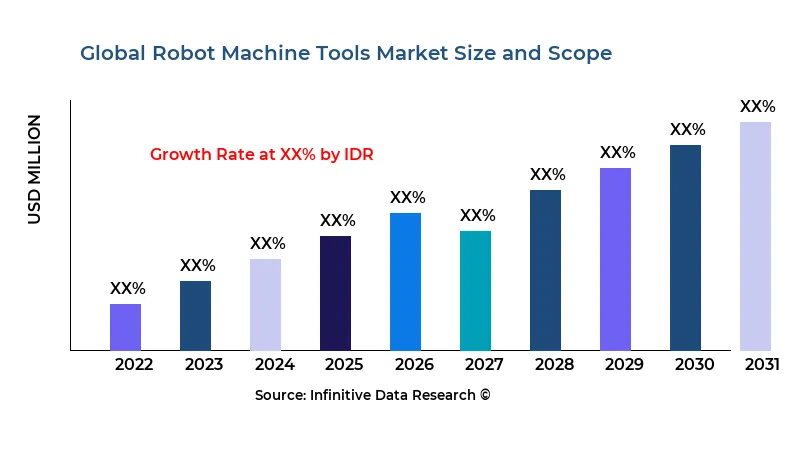

According to research by Infinitive Data Research, the global Robot Machine Tools Market size was valued at USD 6.6 Bln (billion) in 2024 and is Calculated to reach USD 8.6 Bln (billion) by the end of 2032, growing at an anticipated compound annual growth rate (CAGR) of 6.8% during the forecast period 2024 to 2032. This projected growth is driven by its increasing adoption across Machinery & Equipment industries such as Material Handling, Assembly Line, Welding, PaintingThe market for Robot Machine Tools is characterized by the rapid integration of automation in manufacturing, which drives the replacement of traditional machine tools with robotic alternatives. Manufacturers are increasingly investing in automation to reduce cycle times and enhance production efficiency. This shift is not only streamlining production lines but is also fostering a new era of precision engineering where robotic solutions deliver enhanced accuracy and repeatability. Technological advancements continue to reshape the landscape, prompting a wave of innovation in design and functionality.

The evolution in sensor technologies, artificial intelligence, and real-time data analytics has contributed significantly to the market momentum. Robotics manufacturers are now able to offer smart machines that self-optimize and predict maintenance needs, leading to fewer downtimes and improved operational reliability. These improvements have bolstered confidence in robotic solutions among traditional industries that once hesitated to adopt automation. As a result, there is an accelerating trend toward investing in advanced robot machine tools.

Economic factors, such as fluctuating labor costs and competitive global supply chains, are influencing the growth trajectory of this market. With rising wage pressures and a shortage of skilled labor in many regions, companies are turning to robotic machine tools as a sustainable alternative to human-operated equipment. This trend is supported by government initiatives and incentives aimed at modernizing industrial operations. Meanwhile, the increased demand for high-precision manufacturing in sectors like aerospace, automotive, and electronics has further solidified the market’s growth.

Competitive pressures have spurred an environment of continuous improvement and strategic innovation among key players. These companies are leveraging research and development to integrate cutting-edge technologies into their offerings, resulting in machines that are more efficient, adaptable, and user-friendly. This innovation is fostering new business models and service offerings that cater to the evolving demands of modern manufacturing, ensuring that the market remains vibrant and competitive in the long run.

>>> Understand The Key Trends Shaping This Market:- Download PDF Sample

Robot Machine Tools Market Growth Factors

The growth in the robot machine tools market is driven by the need for enhanced productivity and operational efficiency across various industrial sectors. Manufacturers are under constant pressure to meet increasing production targets while reducing error rates and waste. In response, companies are deploying robotic solutions that offer superior precision and consistent performance, thereby significantly cutting down on production costs and rework. This demand for efficiency acts as a strong impetus for market growth.

Advances in technology have led to the development of sophisticated machine tools that integrate seamlessly with digital manufacturing platforms. The increasing availability of smart sensors, cloud-based analytics, and AI-driven process controls have made it possible for these machines to deliver real-time performance insights. This integration not only improves maintenance scheduling and operational uptime but also drives the overall reliability of production systems. As companies prioritize digital transformation, investments in such smart machines are set to rise.

Another key driver is the regulatory and economic environment, which is increasingly supportive of industrial automation. Governments across various regions are offering subsidies and tax incentives to encourage companies to modernize their manufacturing facilities. This supportive policy framework, combined with a robust global economy, has fostered an environment where investments in robotic machine tools are seen as both a necessity and a strategic advantage. These factors are expected to propel market expansion in the foreseeable future.

Furthermore, the competitive nature of the global manufacturing market is prompting businesses to seek every possible edge in terms of quality and cost. The relentless pursuit of innovation by leading players in the field is continually pushing the boundaries of what robot machine tools can achieve. This ongoing innovation cycle is spurring demand as manufacturers look to replace aging equipment with modern, versatile, and more productive systems. The outcome is a steady upward trajectory in market adoption rates, driven by continuous technological and economic factors.

Market Analysis By Competitors

- DAVALL GEARS

- Mitsubishi Heavy Industries

- Nabtesco

- STOBER

- SPINEA

- Stock Drive Products/Sterling Instruments

- VEX Robotics

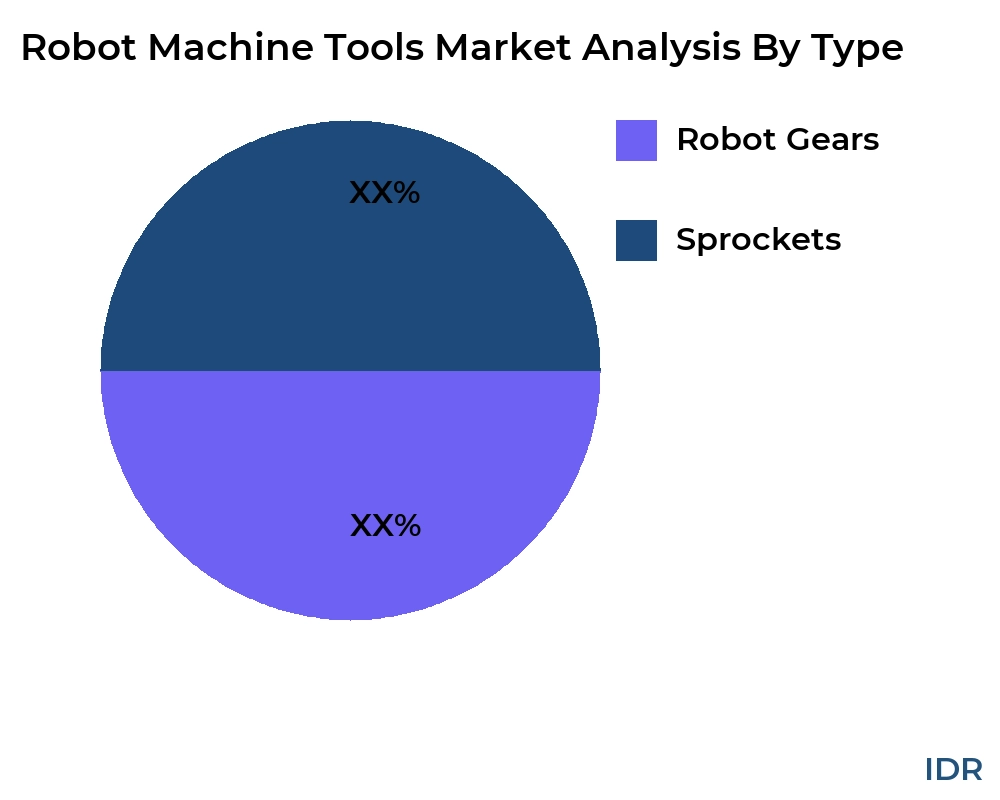

By Product Type

- Robot Gears

- Sprockets

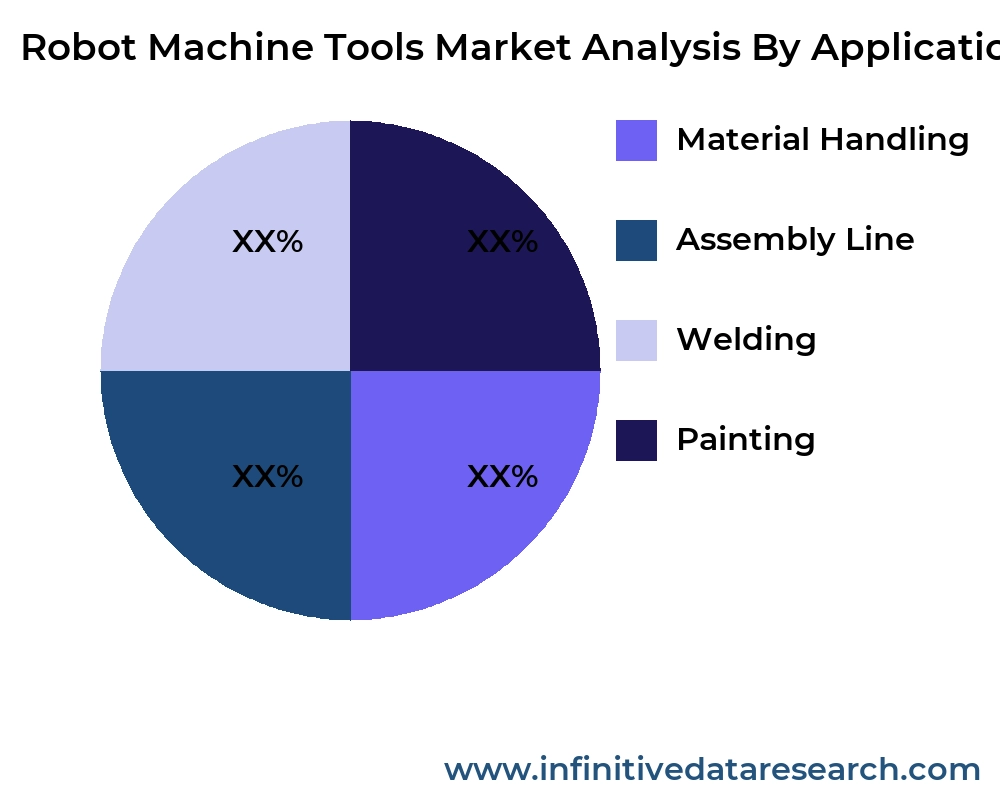

By Application

- Material Handling

- Assembly Line

- Welding

- Painting

>>> Understand The Key Trends Shaping This Market:- Understand The Key Trends Shaping This Market:-

Robot Machine Tools Market Segment Analysis

Distribution Channel:

The market for robot machine tools is segmented by distribution channels that include direct sales, system integrators, and online platforms. Direct sales often involve personalized consultations and tailor-made solutions for large industrial clients, ensuring that every installation meets specific operational needs. System integrators play a critical role in providing turnkey solutions, combining hardware, software, and support services to deliver a comprehensive automation package. Meanwhile, online platforms have emerged as effective channels for smaller-scale implementations and for reaching a broader spectrum of clients. This diversified channel strategy enables manufacturers to cater to a variety of customer requirements and scale operations efficiently.

Compatibility:

In terms of compatibility, robot machine tools are analyzed based on their ability to integrate with legacy systems and modern digital ecosystems. Companies in this market are focusing on developing tools that can easily interface with existing manufacturing execution systems (MES) and enterprise resource planning (ERP) systems. The push for seamless integration is driven by the need to maintain continuity in production while embracing new technologies. This compatibility also extends to modular upgrades, allowing customers to add functionalities as needed. The resulting flexibility not only improves operational efficiency but also enhances the overall adaptability of the manufacturing process.

Price Range:

The market is segmented by price range to accommodate different customer budgets and application scales. High-end solutions target large enterprises looking for state-of-the-art automation capabilities with advanced features and high reliability. Mid-range products cater to medium-sized manufacturers who require a balance between performance and cost efficiency. Lower-priced models are available for smaller manufacturers or as entry-level solutions, providing basic automation functionalities with room for future upgrades. This segmentation ensures that the benefits of robotic machine tools can be accessed across various industrial segments regardless of their scale or financial capacity.

Product Type:

Product type segmentation within the robot machine tools market covers a wide range of offerings from CNC-based systems to specialized robotic arms designed for specific tasks such as welding, assembly, and machining. Manufacturers are continually expanding their product lines to include hybrid systems that combine traditional machine tools with advanced robotics. This diversification in product type caters to niche market demands and helps companies address specialized manufacturing challenges. Each product type is engineered to offer specific advantages, whether it’s enhanced speed, precision, or operational flexibility, thereby meeting the varied needs of a global clientele.

| REPORT ATTRIBUTES | DETAILS |

|---|---|

| Study Period |

2019-2032 |

| Base Year |

2023 |

| Forecast Period |

2024-2032 |

| Historical Period |

2019-2022 |

| Unit |

Value (USD Billion) |

| Key Companies Profiled |

DAVALL GEARS, Mitsubishi Heavy Industries, Nabtesco, STOBER, SPINEA, Stock Drive Products/Sterling Instruments, VEX Robotics |

| Segments Covered |

By Product |

| Customization Scope |

Free report customization (equivalent to up to 3 analyst working days) with purchase. Addition or alteration to country, regional and segment scope |

>>> Overview of Market Analysis:- Download PDF Sample

Robot Machine Tools Market Regional Analysis

The global landscape for robot machine tools is diverse, with significant adoption across North America, Europe, Asia Pacific, and emerging markets. In North America, the market is driven by technological advancements and a strong emphasis on research and development, particularly in high-value sectors such as aerospace and automotive manufacturing. The region’s focus on innovation and quality control is prompting manufacturers to invest heavily in robotic solutions that enhance productivity and reduce human error.

European markets are witnessing robust growth driven by stringent quality standards and a high degree of industrial automation. Countries in Western Europe, in particular, are integrating robot machine tools to maintain competitive advantage in industries that require precision and reliability. This region is characterized by well-established industrial infrastructures and a high adoption rate of advanced technologies, which are further supported by government initiatives and environmental regulations that promote energy-efficient production methods.

The Asia Pacific region, especially in countries like China, Japan, and South Korea, is emerging as a global hub for manufacturing automation. Rapid industrialization, combined with aggressive government policies and a strong focus on technological innovation, is fueling the adoption of robot machine tools. In these markets, companies are investing in cutting-edge automation technologies to meet the demands of large-scale production and to overcome labor shortages. The region’s dynamic economic environment makes it a critical growth engine for the global market.

In emerging markets of Latin America, the Middle East, and Africa, the adoption of robot machine tools is gradually increasing as industries seek to modernize their production capabilities. While the pace of adoption may be slower compared to developed markets, these regions are beginning to see significant investments in automation to enhance competitiveness on a global scale. The drive for improved efficiency and the need to meet international quality standards are prompting companies to gradually adopt robotic solutions, supported by increasing infrastructural improvements and government-led industrial initiatives.

global Robot Machine Tools market revenue (usd million) comparison by players 2024-2032

| Company/players | 2021 | 2022 | 2023 | 2024 | ... | (2032) |

|---|---|---|---|---|---|---|

| DAVALL GEARS | XX | XX | XX | XX | XX | XX |

| Mitsubishi Heavy Industries | XX | XX | XX | XX | XX | XX |

| Nabtesco | XX | XX | XX | XX | XX | XX |

| STOBER | XX | XX | XX | XX | XX | XX |

| SPINEA | XX | XX | XX | XX | XX | XX |

| Stock Drive Products/Sterling Instruments | XX | XX | XX | XX | XX | XX |

| VEX Robotics | XX | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX | XX |

global Robot Machine Tools market revenue (usd million) comparison by product type 2024-2032

Product Type

2023

2024

...

2032

CAGR%(2024-32)

Robot Gears

XX

XX

XX

XX

XX

Sprockets

XX

XX

XX

XX

XX

Total

XX

XX

XX

XX

XX

| Product Type | 2023 | 2024 | ... | 2032 | CAGR%(2024-32) |

|---|---|---|---|---|---|

| Robot Gears | XX | XX | XX | XX | XX |

| Sprockets | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX |

global Robot Machine Tools market revenue (usd million) comparison by application 2024-2032

Application

2023

2024

...

2032

CAGR%(2024-32)

Material Handling

XX

XX

XX

XX

XX

Assembly Line

XX

XX

XX

XX

XX

Welding

XX

XX

XX

XX

XX

Painting

XX

XX

XX

XX

XX

Total

XX

XX

XX

XX

XX

| Application | 2023 | 2024 | ... | 2032 | CAGR%(2024-32) |

|---|---|---|---|---|---|

| Material Handling | XX | XX | XX | XX | XX |

| Assembly Line | XX | XX | XX | XX | XX |

| Welding | XX | XX | XX | XX | XX |

| Painting | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX |

>>> Market Understand Through Graph And Chart:- Download PDF Sample

Robot Machine Tools Market Competitive Insights

The competitive landscape in the robot machine tools market is marked by a blend of established industry giants and innovative startups. Key players are focusing on expanding their portfolios through both organic growth and strategic acquisitions. This competitive spirit is driving rapid technological advancements and the development of new products that address specific industry needs. As companies continue to invest in research and development, the overall quality and capability of robotic machine tools are improving, which in turn is driving market expansion.

A significant trend among competitors is the emphasis on creating modular and scalable solutions. Manufacturers are increasingly designing products that can be customized to suit a variety of applications and production scales. This approach not only enhances customer satisfaction but also allows companies to tap into diverse market segments, from small-scale manufacturing units to large industrial conglomerates. The focus on adaptability and scalability is critical in a market where technological evolution is constant and customer needs are rapidly changing.

Collaborative partnerships and alliances are also a notable aspect of the competitive environment. Leading companies are forming strategic partnerships with technology providers, research institutions, and even end-user industries to jointly develop next-generation automation solutions. These collaborations are accelerating the pace of innovation and ensuring that new products are both technologically advanced and market ready. The mutual exchange of expertise and resources is enabling companies to respond more quickly to market demands and to create solutions that are both comprehensive and future-proof.

Despite intense competition, market leaders continue to dominate through their established brand reputation, extensive distribution networks, and comprehensive service offerings. These companies are leveraging their global presence to gain insights into regional market trends and to tailor their offerings accordingly. The emphasis on customer support, after-sales services, and continuous product improvement is ensuring that even as new entrants join the market, established players retain a significant competitive edge.

Robot Machine Tools Market Competitors

United States:

- ABB Robotics

- FANUC America

- Rockwell Automation

- KUKA Robotics

- Yaskawa Motoman

Germany:

- KUKA AG

- Siemens AG

- Trumpf GmbH

- DMG Mori AG

- Festo AG

Japan:

- FANUC Corporation

- Kawasaki Robotics

- Mitsubishi Electric Automation

- Yaskawa Electric Corporation

- Omron Adept Technologies

South Korea:

- Hyundai Robotics

- Doosan Robotics

- LS Industrial Systems

- Hanwha Precision Machinery

- Denso Robotics

China:

- Siasun Robot & Automation

- Estun Automation

- Greatoo Intelligent Equipment

- Efort Intelligent Equipment

- JAKA Robotics

Italy:

- Comau Robotics

- ABB Italy

- Prima Industrie

- Biesse Group

- Omron Robotics Italy

Robot Machine Tools Market Top Competitors

1. ABB Robotics

ABB Robotics is a leading provider of industrial automation solutions with a rich history of innovation in robotics technology. The company consistently invests in research and development to push the boundaries of automation and digitalization. With a strong global presence, ABB has become synonymous with reliability and high-quality robot machine tools. The organization maintains a strong focus on sustainability and energy efficiency in its product designs. As a market leader, ABB continues to influence industry trends and shape the future of robotics.

2. FANUC Corporation

FANUC Corporation is renowned for its cutting-edge robotics and automation systems that cater to various industries including automotive, electronics, and metalworking. The company has a reputation for delivering high-performance and reliable solutions that significantly boost productivity. FANUC’s technological advancements have led to a range of products that are adaptable and easy to integrate into existing manufacturing processes. It is also known for its continuous improvement initiatives and comprehensive after-sales support. This has solidified its position as a top competitor in the market.

3. KUKA AG

KUKA AG is a global leader in robotics with extensive expertise in providing machine tools that enhance production efficiency. The company is celebrated for its innovative approach, leveraging advanced technologies to develop adaptable and high-precision robotic systems. KUKA’s solutions are widely used in industries ranging from automotive to electronics, where reliability and precision are paramount. With a significant focus on sustainability and digitalization, KUKA continues to lead in developing next-generation automation solutions. Its global network and strategic partnerships further reinforce its market position.

4. Yaskawa Electric Corporation

Yaskawa Electric Corporation has established itself as a pioneer in the robotics field by delivering robust and innovative automation solutions. The company’s product portfolio includes highly sophisticated machine tools that cater to diverse industrial applications. Yaskawa’s focus on continuous technological improvement and customer-centric innovations has earned it a strong reputation worldwide. Its ability to provide comprehensive solutions that integrate seamlessly with existing systems distinguishes it from competitors. Yaskawa remains at the forefront of industry trends and is a key player in the automation landscape.

5. DMG Mori AG

DMG Mori AG is recognized for its precision machine tools and robust automation solutions that serve a broad range of manufacturing sectors. The company’s integration of advanced robotics into its product lineup has enhanced operational efficiency and precision for its customers. DMG Mori AG’s commitment to innovation and quality has led to numerous breakthroughs in manufacturing technology. Its products are known for their durability and adaptability in complex production environments. As a top competitor, DMG Mori continues to drive forward the evolution of industrial automation.

6. Siemens AG

Siemens AG is a key player in industrial automation, offering a wide range of digitalized machine tools and robotics solutions. With a strong emphasis on research and development, Siemens continuously introduces innovative technologies that streamline manufacturing processes. Its products are designed to integrate smoothly into modern digital infrastructures, ensuring operational efficiency and data-driven decision-making. Siemens AG has a global footprint, supporting industries through comprehensive solutions that cater to both large-scale and niche markets. Its strategic vision and customer focus have positioned it as a market leader.

7. Kawasaki Robotics

Kawasaki Robotics stands out for its high-performance robotic systems that deliver exceptional precision and speed. The company’s solutions are widely utilized in industries that demand accuracy and reliability in repetitive tasks. Kawasaki’s focus on developing robust and flexible automation systems has enabled it to build a strong market presence. Its continued investment in innovative technologies ensures that its products remain competitive and in line with industry trends. The company’s commitment to quality and innovation is reflected in its strong performance in the global market.

8. Mitsubishi Electric Automation

Mitsubishi Electric Automation is widely recognized for its comprehensive range of robotic solutions that enhance manufacturing productivity. The company offers highly reliable machine tools that are known for their performance in high-speed and precision-driven environments. Mitsubishi’s products are designed to meet the stringent demands of modern manufacturing processes while ensuring ease of integration and scalability. Its robust research and development capabilities support continuous product enhancements. As a major competitor, Mitsubishi Electric remains a trusted name in industrial automation.

9. Omron Adept Technologies

Omron Adept Technologies is known for its innovative automation solutions that cater to diverse industrial applications. The company focuses on developing robotic systems that are both intelligent and flexible, capable of meeting the evolving needs of manufacturing industries. Its product range includes state-of-the-art machine tools that integrate seamlessly with digital platforms. Omron Adept’s commitment to technological advancement and customer service has helped it secure a significant share in the market. The company’s emphasis on innovation continues to drive its competitive edge.

10. Rockwell Automation

Rockwell Automation is a prominent player in the automation sector, providing comprehensive solutions that blend machine tools with advanced robotics. The company’s products are engineered to improve efficiency, reduce downtime, and optimize overall production performance. Rockwell’s integrated approach ensures that its robotic solutions are adaptable to various manufacturing environments. The organization’s strong focus on digital transformation and connectivity has positioned it as a leader in the market. Its sustained innovation and customer-centric strategies continue to propel its growth and market presence.

The report provides a detailed analysis of the Robot Machine Tools market across various regions, highlighting the unique market dynamics and growth opportunities in each region.

- US

- Canada

- Mexico

- UK

- Germany

- France

- Italy

- Russia

- Spain

- Switzerland

- Austria

- Belgium

- Rest of Europe

- China

- Japan

- South Korea

- Indonesia

- Vietnam

- Philippines

- Australia

- Thailand

- Singapore

- Rest of APAC

- UAE

- Saudi Arabia

- Egypt

- South Africa

- Israel

- Rest of MEA

- Brazil

- Argentina

- Rest of Latin America

>>> Need A Different Region Or Segment? Download PDF Sample

Key Takeaways

- The global Robot Machine Tools market is expected to grow significantly from 2024 to 2032, driven by technological advancements, increasing demand, and government investments in urbanization.

- The market is characterized by a diverse range of manufacturers, product types, and applications, catering to different consumer needs and preferences.

- Regional insights highlight the unique market dynamics and growth opportunities in various regions, including North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

- The competitive landscape features key players who have created a dynamic and diverse market environment through collaborations, mergers and acquisitions, and innovative product developments.

- Market trends such as technological advancements, sustainability, customization, and digital transformation are shaping the growth and development of the Robot Machine Tools market.

- Despite the positive outlook, the market faces challenges such as regulatory compliance, high initial investment costs, and economic uncertainties.

- The report provides comprehensive coverage of market size, market share, growth factors, and strategic insights to help businesses navigate the dynamic Robot Machine Tools market and achieve long-term success.

By leveraging the information provided in this report, businesses can develop effective strategies, address market challenges, and capitalize on growth opportunities to ensure sustainable growth and long-term success in the global Robot Machine Tools market.

- Introduction

- Objectives of the Study

- Market Definition

- Research Scope

- Currency

- Key Target Audience

- Research Methodology and Assumptions

- Executive Summary

- Premium Insights

- Porter’s Five Forces Analysis

- Value Chain Analysis

- Top Investment Pockets

- Industry Trends

- Market Dynamics

- Market Evaluation

- Drivers

- Restraints

- Opportunities

- Challenges

- Global Robot Machine Tools Market Analysis and Projection, By Companies

- Segment Overview

- DAVALL GEARS

- Mitsubishi Heavy Industries

- Nabtesco

- STOBER

- SPINEA

- Stock Drive Products/Sterling Instruments

- VEX Robotics

- Global Robot Machine Tools Market Analysis and Projection, By Type

- Segment Overview

- Robot Gears

- Sprockets

- Global Robot Machine Tools Market Analysis and Projection, By Application

- Segment Overview

- Material Handling

- Assembly Line

- Welding

- Painting

- Global Robot Machine Tools Market Analysis and Projection, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Russia

- Spain

- Switzerland

- Austria

- Belgium

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Vietnam

- Philippines

- Australia

- Thailand

- Singapore

- Rest of APAC

- Middle East

- UAE

- Saudi Arabia

- Egypt

- South Africa

- Israel

- Rest of MEA

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Global Robot Machine Tools Market-Competitive Landscape

- Overview

- Market Share of Key Players in the Robot Machine Tools Market

- Global Company Market Share

- North America Company Market Share

- Europe Company Market Share

- APAC Company Market Share

- Competitive Situations and Trends

- Coverage Launches and Developments

- Partnerships, Collaborations, and Agreements

- Mergers & Acquisitions

- Expansions

- Company Profiles

- DAVALL GEARS

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Mitsubishi Heavy Industries

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Nabtesco

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- STOBER

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- SPINEA

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Stock Drive Products/Sterling Instruments

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- VEX Robotics

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

List of Table

- Drivers of Global Robot Machine Tools Market: Impact Analysis

- Restraints of Global Robot Machine Tools Market: Impact Analysis

- Global Robot Machine Tools Market, By Technology, 2023-2032(USD Billion)

- global Robot Gears, Robot Machine Tools Market, By Region, 2023-2032(USD Billion)

- global Sprockets, Robot Machine Tools Market, By Region, 2023-2032(USD Billion)

- global Material Handling, Robot Machine Tools Market, By Region, 2023-2032(USD Billion)

- global Assembly Line, Robot Machine Tools Market, By Region, 2023-2032(USD Billion)

- global Welding, Robot Machine Tools Market, By Region, 2023-2032(USD Billion)

- global Painting, Robot Machine Tools Market, By Region, 2023-2032(USD Billion)

List of Figures

- Global Robot Machine Tools Market Segmentation

- Robot Machine Tools Market: Research Methodology

- Market Size Estimation Methodology: Bottom-Up Approach

- Market Size Estimation Methodology: Top-down Approach

- Data Triangulation

- Porter’s Five Forces Analysis

- Value Chain Analysis

- Top investment pocket in the Robot Machine Tools Market

- Top Winning Strategies, 2023-2032

- Top Winning Strategies, By Development, 2023-2032(%)

- Top Winning Strategies, By Company, 2023-2032

- Moderate Bargaining power of Buyers

- Moderate Bargaining power of Suppliers

- Moderate Bargaining power of New Entrants

- Low threat of Substitution

- High Competitive Rivalry

- Restraint and Drivers: Robot Machine Tools Market

- Robot Machine Tools Market Segmentation, By Technology

- Robot Machine Tools Market For Live Attenuated, By Region, 2023-2033 ($ Billion)

- Global Robot Machine Tools Market, By Technology, 2023-2032(USD Billion)

- global Robot Gears, Robot Machine Tools Market, By Region, 2023-2032(USD Billion)

- global Sprockets, Robot Machine Tools Market, By Region, 2023-2032(USD Billion)

- global Material Handling, Robot Machine Tools Market, By Region, 2023-2032(USD Billion)

- global Assembly Line, Robot Machine Tools Market, By Region, 2023-2032(USD Billion)

- global Welding, Robot Machine Tools Market, By Region, 2023-2032(USD Billion)

- global Painting, Robot Machine Tools Market, By Region, 2023-2032(USD Billion)

- DAVALL GEARS: Net Sales, 2023-2033 ($ Billion)

- DAVALL GEARS: Revenue Share, By Segment, 2023 (%)

- DAVALL GEARS: Revenue Share, By Region, 2023 (%)

- Mitsubishi Heavy Industries: Net Sales, 2023-2033 ($ Billion)

- Mitsubishi Heavy Industries: Revenue Share, By Segment, 2023 (%)

- Mitsubishi Heavy Industries: Revenue Share, By Region, 2023 (%)

- Nabtesco: Net Sales, 2023-2033 ($ Billion)

- Nabtesco: Revenue Share, By Segment, 2023 (%)

- Nabtesco: Revenue Share, By Region, 2023 (%)

- STOBER: Net Sales, 2023-2033 ($ Billion)

- STOBER: Revenue Share, By Segment, 2023 (%)

- STOBER: Revenue Share, By Region, 2023 (%)

- SPINEA: Net Sales, 2023-2033 ($ Billion)

- SPINEA: Revenue Share, By Segment, 2023 (%)

- SPINEA: Revenue Share, By Region, 2023 (%)

- Stock Drive Products/Sterling Instruments: Net Sales, 2023-2033 ($ Billion)

- Stock Drive Products/Sterling Instruments: Revenue Share, By Segment, 2023 (%)

- Stock Drive Products/Sterling Instruments: Revenue Share, By Region, 2023 (%)

- VEX Robotics: Net Sales, 2023-2033 ($ Billion)

- VEX Robotics: Revenue Share, By Segment, 2023 (%)

- VEX Robotics: Revenue Share, By Region, 2023 (%)

Infinitive Data Research provides comprehensive market research, offering in-depth market analysis to help companies understand their target market and industry competition. This research predicts the market acceptance of your brand and products, ensuring informed decision-making for business success.

Competitor Analysis in the Robot Machine Tools Industry

Conducting a competitor analysis involves identifying competitors within the Robot Machine Tools industry and studying their various marketing strategies. This comparative data allows you to assess your company's strengths and weaknesses relative to competitors, providing insights to enhance your market position.

Importance of Continuous Market Research

Consistently conducting market research is essential for minimizing risk at every stage of business operations. Robot Machine Tools market research enables you to collect qualitative and quantitative data, which, when properly analyzed, leads to wise decisions that align with user and customer needs. Below are some crucial lessons learned through the Robot Machine Tools market research process:

Key Dimensions of Robot Machine Tools Market Analysis

- Trend and Pattern Identification: Analyzing data to spot market trends and patterns.

- Pricing Analysis: Assessing keyword pricing strategies.

- Actionable Insights: Implementing insights derived from data analysis.

- Market Potential: Evaluating the potential of the Robot Machine Tools market.

- Competitor Analysis: Studying competitors' strategies and performance.

- Location Analysis: Assessing optimal locations for market penetration.

- Distribution Channels Analysis: Evaluating the effectiveness of distribution channels.

- Market Size and Growth Rate: Measuring market size and growth potential.

- Market Profitability: Assessing profitability prospects.

- Key Success Factors: Identifying critical factors for success.

- Cost Structure: Understanding the cost structure within the Robot Machine Tools industry.

Target Audience for the Report

This report is valuable for a diverse audience, including:

- Robot Machine Tools Market Manufacturers: To understand market dynamics and enhance production strategies.

- Investors and Financing Companies: To assess investment opportunities and risks.

- Robot Machine Tools Market Suppliers: To identify market demands and supply chain efficiencies.

Necessity of the Report

Making Crucial Business Decisions

Understanding the Robot Machine Tools market, competition, and industry landscape is vital for making informed business decisions. Without current and relevant market research, decisions may be based on outdated or irrelevant information, potentially harming the business.

Securing Investment Funds

Attracting investors requires demonstrating thorough market research. Investors need assurance that you understand the sector, current and potential competition, and whether your idea addresses a market need.

Identifying New Business Opportunities

Robot Machine Tools market research goes beyond understanding trends and consumer behavior. It identifies new revenue streams and opportunities for business pivots. These insights can lead to strategic changes in the business model, promoting growth and adapting to market challenges.

Avoiding Business Failures

Market research also plays a crucial role in risk mitigation. It can reveal when not to pursue certain actions, saving the company from potential losses in revenue, brand image, and more. This proactive approach is often overlooked but is essential for long-term success.

Conclusion

Infinitive Data Research's comprehensive Robot Machine Tools market research provides critical insights for making solid business decisions, securing investments, identifying new opportunities, and avoiding potential failures. Understanding market dynamics through continuous research ensures your company remains competitive and thrives in the Robot Machine Tools industry.