Polymeric Polyol Market Growth CAGR Overview

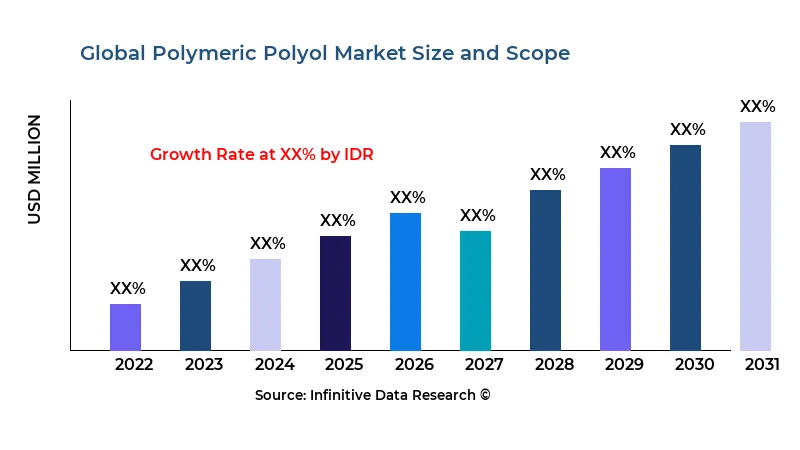

According to research by Infinitive Data Research, the global Polymeric Polyol Market size was valued at USD 7.6 Bln (billion) in 2024 and is Calculated to reach USD 10.9 Bln (billion) by the end of 2032, growing at an anticipated compound annual growth rate (CAGR) of 6.6% during the forecast period 2024 to 2032. This projected growth is driven by its increasing adoption across Chemical & Materials industries such as Drugs, Chemical Products, OtherThe polymeric polyol market is deeply intertwined with the global polyurethane industry, which utilizes these multifunctional intermediates to produce flexible foams, rigid foams, coatings, adhesives, sealants, and elastomers. Innovations in polyol chemistry—such as bio‑based feedstocks, tailored functionality, and controlled molecular weight distributions—are driving the development of next‑generation polyurethanes with enhanced performance characteristics. Polymeric polyols with precisely adjusted hydroxyl numbers and functionalities enable formulators to fine‑tune foam resilience, thermal insulation properties, and mechanical strength across diverse end‑use applications.

Sustainability imperatives are reshaping market dynamics as regulatory agencies and end‑users demand lower volatile organic compound (VOC) emissions, reduced carbon footprints, and increased use of renewable resources. Manufacturers are investing in bio‑polyol technologies derived from plant oils, glycerol by‑products, and carbohydrate‑based intermediates. These bio‑derived polyols not only address environmental concerns but also offer cost advantages in regions where agricultural feedstocks are abundant. The integration of lifecycle assessment (LCA) data into product development is becoming commonplace, enabling customers to quantify environmental benefits and secure green certifications.

Global supply chain considerations factor prominently, as feedstock availability—particularly propylene oxide and ethylene oxide—can be affected by petrochemical market volatility and logistic constraints. Leading polyol producers are establishing integrated production sites adjacent to upstream petrochemical facilities to secure consistent raw material flows and reduce transportation costs. Strategic partnerships between polyol producers and isocyanate manufacturers are also emerging, ensuring co‑development of optimized resin systems and streamlined supply chains. This vertical collaboration is enhancing product innovation while mitigating risk across the value chain.

The competitive landscape is characterized by consolidation among major chemical conglomerates and the entry of specialized regional players offering tailored product portfolios. Large multinationals leverage global R&D networks to accelerate the commercialization of novel polyol grades, while smaller firms focus on niche segments—such as high‑functionality polyols for advanced elastomers or low‑temperature foaming systems. Licensing agreements and joint ventures facilitate technology transfer and local manufacturing capabilities, enabling rapid market penetration in Asia Pacific, Latin America, and the Middle East & Africa regions.

>>> Understand The Key Trends Shaping This Market:- Download PDF Sample

Polymeric Polyol Market Growth Factors

Robust growth in end‑use industries such as automotive seating, construction insulation, and consumer electronics underpins rising demand for polymeric polyols. The ongoing shift towards lightweight materials in automotive design is driving the adoption of flexible polyurethane foams with superior comfort and crash‑resistance properties. Similarly, stringent building energy codes worldwide are accelerating the use of rigid polyurethane insulation panels, which rely on high‑performance polymeric polyols to achieve low thermal conductivity and structural integrity. As emerging economies invest heavily in infrastructure and residential construction, the downstream demand for polyol‑based polyurethane systems continues to expand.

Innovation in bio‑based and sustainable polyol technologies is a key growth enabler, as formulators seek to reduce dependency on petrochemical feedstocks and meet corporate sustainability targets. The use of renewable feedstocks—such as soybean, castor, and palm oils—coupled with catalytic processes to introduce functional groups, has given rise to a new class of polymeric polyols with competitive performance profiles. These bio‑polyols not only lower the carbon footprint of final products but also appeal to eco‑conscious consumers in sectors like furniture, bedding, and footwear. As production costs for bio‑feedstocks decline, wider adoption of bio‑based polyols is anticipated.

Advances in polyol customization and reactive formulations have unlocked new application spaces, particularly in high‑performance coatings and adhesives. Polymeric polyols with higher functionality and tailored molecular weights enable the production of coatings with enhanced scratch resistance, chemical stability, and adhesion properties. In the adhesives market, specialized polyols contribute to one‑component and two‑component systems that cure rapidly under ambient conditions, expanding their use in automotive assembly and industrial fabrication. This trend toward application‑specific polyols fuels incremental innovation and drives overall market growth.

Global expansion of refrigerated transportation and cold‑chain logistics is bolstering demand for rigid polyurethane foams with superior insulating properties. The growth of e‑commerce, pharmaceuticals, and perishable food shipments has prompted significant investments in refrigerated vehicles and insulated containers, all of which rely on polymeric polyol‑based foam systems. The need for lightweight yet highly insulative materials to maintain temperature control during transit underscores the importance of high‑quality polyol intermediates. As the cold‑chain network grows, so too does the consumption of polymeric polyols in refrigeration and thermal management solutions.

Market Analysis By Competitors

- Covestro

- BASF

- Cargill

- The Essential Chemical

- Stepan Company

- Bossco Industries

- SKC

- Huntsman

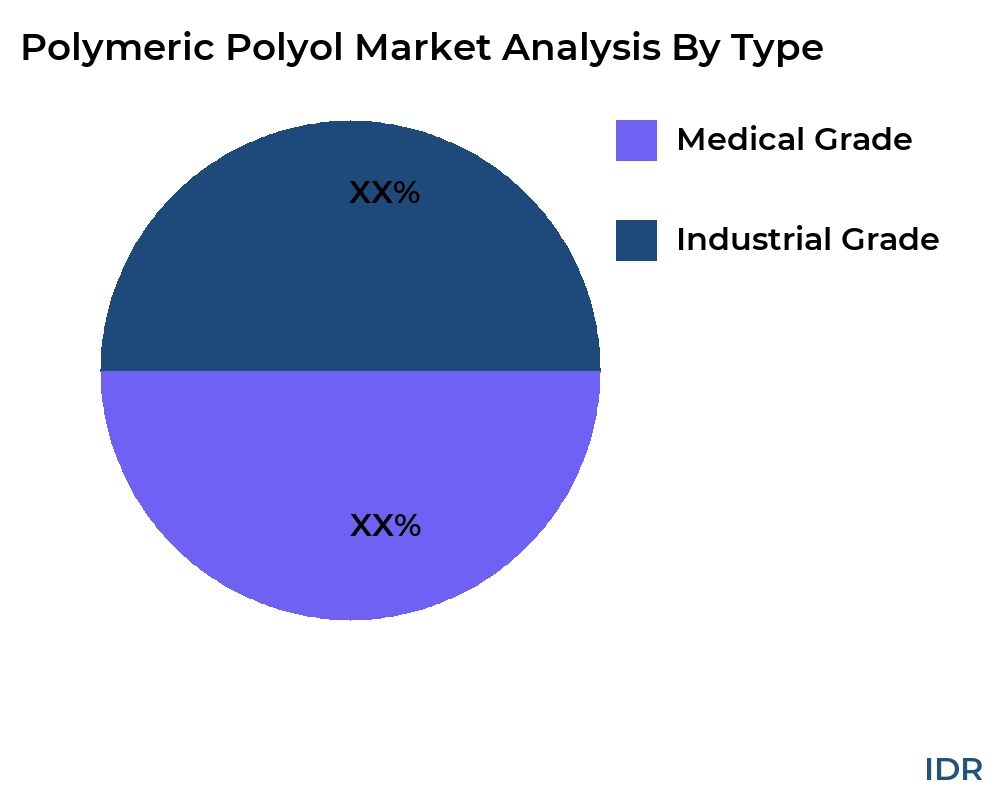

By Product Type

- Medical Grade

- Industrial Grade

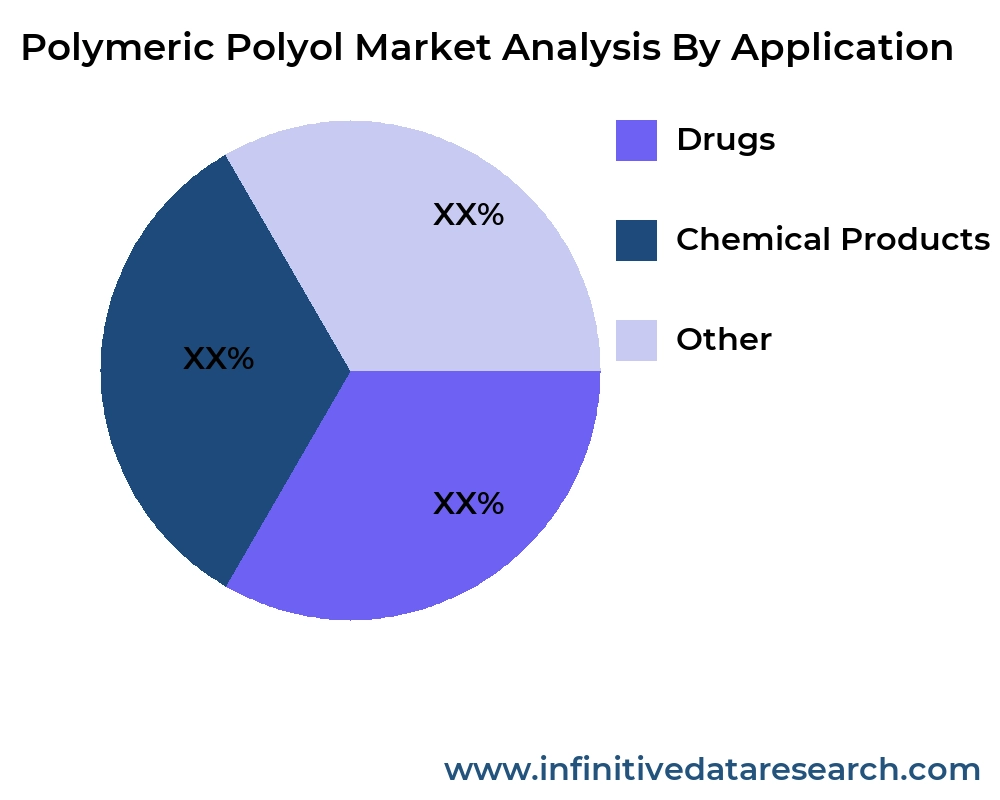

By Application

- Drugs

- Chemical Products

- Other

>>> Understand The Key Trends Shaping This Market:- Understand The Key Trends Shaping This Market:-

Polymeric Polyol Market Segment Analysis

Distribution Channel:

The polymeric polyol market employs a combination of direct sales and chemical distribution networks to reach end‑use formulators. Large chemical producers often engage directly with major polyurethane manufacturers through long‑term supply agreements and co‑development projects. Smaller polyol producers and regional suppliers leverage specialty chemical distributors to access niche markets and small‑batch consumers such as coatings formulators and adhesives producers. Distribution partners provide value‑added services—such as technical support, sampling, and inventory management—ensuring that customers receive tailored product recommendations and just‑in‑time deliveries to streamline their production processes.

Compatibility:

Compatibility is critical in polyol selection, as polyols must react predictably with various isocyanate grades to achieve targeted polymer architectures. Polymeric polyols are engineered with specific hydroxyl numbers, molecular weights, and functionalities to match the reactivity profiles of TDI, MDI, and aliphatic isocyanates. Formulators require polyols that maintain consistent viscosity and miscibility under diverse processing conditions, including spray foaming, continuous lamination, and reactive extrusion. Technical support services, including rheological testing and reaction profiling, play an important role in ensuring compatibility and performance consistency across batches.

Price:

The price of polymeric polyols is influenced by feedstock costs, production scale, and purity specifications. Commodity polyols derived from petrochemical streams enjoy cost advantages due to large‑scale integrated operations, whereas specialty polyols with higher functionality or bio‑based content command premiums. Price volatility in propylene oxide and ethylene oxide markets directly impacts polyol pricing, prompting some producers to implement feedstock hedging strategies or develop alternative synthesis routes. Cost optimization also arises from process innovations—such as continuous manufacturing and advanced catalyst systems—that improve yields and reduce energy consumption, enabling producers to offer more competitive pricing without sacrificing quality.

Product Type:

Product types in the polymeric polyol market are differentiated by functionality (diol, triol, polyol), molecular weight range, viscosity, and bio‑based content. Low‑functionality polyols (e.g., diols and triols) serve as building blocks for flexible foams and elastomers, while higher‑functionality polymeric polyols are tailored for rigid foams and high‑crosslink density coatings. Specialty grades include aromatic, aliphatic, and polyester‑based polyols, each offering unique performance profiles in terms of thermal stability, chemical resistance, and mechanical strength. The emergence of hybrid polyols—combining polyester and polyether segments—provides formulators with balanced properties for demanding applications such as automotive underbody coatings and high‑durability adhesives.

| REPORT ATTRIBUTES | DETAILS |

|---|---|

| Study Period |

2019-2032 |

| Base Year |

2023 |

| Forecast Period |

2024-2032 |

| Historical Period |

2019-2022 |

| Unit |

Value (USD Billion) |

| Key Companies Profiled |

Covestro, BASF, Cargill, The Essential Chemical, Stepan Company, Bossco Industries, SKC, Huntsman |

| Segments Covered |

By Product |

| Customization Scope |

Free report customization (equivalent to up to 3 analyst working days) with purchase. Addition or alteration to country, regional and segment scope |

>>> Overview of Market Analysis:- Download PDF Sample

Polymeric Polyol Market Regional Analysis

In North America, a mature polyurethane industry and strong automotive and construction sectors underpin robust demand for polymeric polyols. The region benefits from advanced petrochemical infrastructure, enabling efficient production of ethylene oxide and propylene oxide precursors. Sustainability initiatives—such as California’s Low Carbon Fuel Standard—are driving adoption of bio‑based polyols and recycled feedstocks. Collaboration between universities, national labs, and industry consortia fosters continuous innovation in polymer chemistry, ensuring that North American producers remain at the cutting edge of performance and environmental stewardship.

Europe’s market for polymeric polyols is shaped by stringent environmental regulations and strong demand for high‑performance foams in building insulation and automotive applications. The EU’s circular economy action plan and REACH regulations incentivize the use of recycled and bio‑based polyols, leading to significant R&D investments in green chemistry technologies. European producers often co‑locate with integrated isocyanate and polyurethane manufacturing sites, enhancing supply chain resilience and reducing logistics emissions. The regional focus on energy efficiency in buildings and lightweight mobility solutions continues to support healthy growth in polyol consumption.

Asia‑Pacific stands as the fastest‑growing regional market, propelled by rapid industrialization, urbanization, and a burgeoning automotive sector in China, India, and Southeast Asia. Low labor costs and expanding petrochemical capacities attract global polyol producers to establish manufacturing hubs in the region. Domestic formulators in countries like China and India are increasingly investing in advanced polyurethane systems, partnering with global polyol suppliers to upgrade local production capabilities. Government incentives for building energy efficiency and domestic electric vehicle adoption are further accelerating demand for specialized polymeric polyols in insulation and automotive seating applications.

In Latin America and the Middle East & Africa (MEA), market growth is driven by infrastructure development and rising demand for consumer goods. Regional producers are gradually expanding their capabilities to supply domestic PVC, PU, and coating industries. Political and economic volatility can impact feedstock availability, prompting some formulators to secure long‑term supply contracts with multinational chemical companies. Investments in local distribution networks and technical service centers aim to support end‑users with product selection and formulation expertise. As construction and manufacturing activities scale up, these emerging regions offer significant opportunities for polymeric polyol consumption.

global Polymeric Polyol market revenue (usd million) comparison by players 2024-2032

| Company/players | 2021 | 2022 | 2023 | 2024 | ... | (2032) |

|---|---|---|---|---|---|---|

| Covestro | XX | XX | XX | XX | XX | XX |

| BASF | XX | XX | XX | XX | XX | XX |

| Cargill | XX | XX | XX | XX | XX | XX |

| The Essential Chemical | XX | XX | XX | XX | XX | XX |

| Stepan Company | XX | XX | XX | XX | XX | XX |

| Bossco Industries | XX | XX | XX | XX | XX | XX |

| SKC | XX | XX | XX | XX | XX | XX |

| Huntsman | XX | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX | XX |

global Polymeric Polyol market revenue (usd million) comparison by product type 2024-2032

Product Type

2023

2024

...

2032

CAGR%(2024-32)

Medical Grade

XX

XX

XX

XX

XX

Industrial Grade

XX

XX

XX

XX

XX

Total

XX

XX

XX

XX

XX

| Product Type | 2023 | 2024 | ... | 2032 | CAGR%(2024-32) |

|---|---|---|---|---|---|

| Medical Grade | XX | XX | XX | XX | XX |

| Industrial Grade | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX |

global Polymeric Polyol market revenue (usd million) comparison by application 2024-2032

Application

2023

2024

...

2032

CAGR%(2024-32)

Drugs

XX

XX

XX

XX

XX

Chemical Products

XX

XX

XX

XX

XX

Other

XX

XX

XX

XX

XX

Total

XX

XX

XX

XX

XX

| Application | 2023 | 2024 | ... | 2032 | CAGR%(2024-32) |

|---|---|---|---|---|---|

| Drugs | XX | XX | XX | XX | XX |

| Chemical Products | XX | XX | XX | XX | XX |

| Other | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX |

>>> Market Understand Through Graph And Chart:- Download PDF Sample

Polymeric Polyol Market Competitive Insights

The polymeric polyol market is characterized by a concentrated set of global chemical majors that dominate upstream feedstock integration, advanced R&D, and large‑scale production. These incumbents leverage economies of scale and deep technical expertise to introduce novel polyols with tailored performance and sustainability attributes. Their global manufacturing footprint ensures consistent supply and rapid response to demand shifts, while extensive application development labs support customers in fine‑tuning formulations. Market leadership is maintained through strategic acquisitions and joint ventures, enabling continued expansion into bio‑based and specialty polyol segments.

Regional and specialized producers differentiate themselves through niche product offerings and close customer engagement. These smaller players often excel in customizing polyol grades for specific applications, providing rapid sample turnaround and technical support to niche formulators. Flexibility in production scale and willingness to collaborate on co‑development projects give them an edge in applications requiring unique polyol chemistries—such as high‑rebound elastomers or ultra‑low‑density foams. Their agility allows them to address emerging market trends more quickly than larger conglomerates, fostering innovation in specialized segments.

Collaborations across the value chain are reshaping competitive dynamics, as polyol producers partner with isocyanate suppliers, equipment manufacturers, and end‑users to co‑innovate complete polyurethane systems. These integrated partnerships reduce development timelines and ensure compatibility across components, resulting in more reliable and efficient formulations. Such strategic alliances also leverage shared R&D costs and risk, enabling the introduction of high‑value products like bio‑based polyols and advanced reactive additives. As a result, the market is evolving toward holistic solution providers rather than standalone raw material suppliers.

Sustainability and circularity initiatives are emerging as critical competitive differentiators. Companies that can demonstrate cradle‑to‑grave lifecycle management—incorporating renewable feedstocks, energy‑efficient production, and end‑of‑life recyclability—are gaining favor among environmentally conscious customers. The ability to supply mass‑balance certified bio‑polyols or offer closed‑loop recycling programs for polyurethane foam waste is translating into premium pricing and long‑term contract advantages. This shift toward green polyols is driving consolidation of smaller bio‑polyol specialists by larger chemical groups seeking to bolster their sustainability credentials.

Polymeric Polyol Market Competitors

United States

-

The Dow Chemical Company

-

Huntsman Corporation

-

Covestro LLC

-

BASF Corporation (U.S. operations)

-

Stepan Company

Germany

-

BASF SE

-

Covestro AG

-

Evonik Industries AG

-

Bayer AG (Polyurethane division)

-

Lanxess AG

Japan

-

Mitsui Chemicals, Inc.

-

Sumitomo Chemical Co., Ltd.

-

AGC Inc. (Formerly Asahi Glass)

-

DIC Corporation

-

Kuraray Co., Ltd.

China

-

Wanhua Chemical Group Co., Ltd.

-

Yantai Wanhua Polyurethane Co., Ltd.

-

Kingfa Sci & Tech Co., Ltd.

-

Shanghai International Chemical Co., Ltd.

-

Shandong Haoyu Polyurethane Co., Ltd.

South Korea

-

LG Chem Ltd.

-

Lotte Chemical Corporation

-

Kumho Petrochemical Co., Ltd.

-

SKC Co., Ltd.

-

Hanwha Chemical Corporation

India

-

PI Industries Ltd.

-

Atul Ltd.

-

Bhansali Engineering Polymers Ltd.

-

Jayant Agro-Organics Ltd.

-

Meghmani Organics Ltd.

Polymeric Polyol Market Top Competitors

1. The Dow Chemical Company

Dow Chemical is a storied leader in the polymeric polyol market, leveraging its global petrochemical integration and decades of materials science expertise. The company produces a wide range of polyether and polyester polyols, serving flexible and rigid foam, elastomer, and coating applications. Dow’s proprietary catalyst and process technologies enable precise control over polyol molecular weight distribution and functionality, critical for high‑performance polyurethane systems. With major production sites across North America, Europe, and Asia, Dow ensures supply reliability and rapid product customization. Its extensive application development centers collaborate closely with OEMs and formulators to co‑innovate bio‑based polyols and low‑VOC solutions, reinforcing Dow’s reputation as an innovation powerhouse.

2. BASF SE

BASF stands among the top global chemical producers with a robust polymeric polyol portfolio tailored to diverse polyurethane markets. The company’s research focuses on high‑functionality polyols for specialty elastomers and high‑density formulations, as well as bio‑based polyols derived from renewable resources. BASF’s integrated production capabilities—from ethylene oxide and propylene oxide upstream to finished polyols—provide cost advantages and supply security. The company invests heavily in digitalization of its supply chain and advanced process analytics to maximize operational efficiency and sustainability. Strategic partnerships with automotive and construction industry leaders yield turnkey insulation and seating solutions, cementing BASF’s competitive position in key end‑use sectors.

3. Covestro AG

Covestro is a leading innovator in polymeric polyols, particularly in the development of coating, adhesive, sealant, and elastomer (CASE) grade polyols. Its portfolio includes specialty polyols with low viscosity, high functionality, and improved hydrolytic stability designed for high‑performance CASE applications. Covestro’s research collaborations with automotive OEMs and construction material providers drive early adoption of next‑generation polyurethanes with lightweight and durable properties. The company’s global network of integrated sites and technical service laboratories enhances customer responsiveness and ensures consistent product performance. As part of its sustainability agenda, Covestro is pioneering the use of carbon dioxide‑based polyols and mass‑balance certified bio‑polyols to reduce the environmental footprint of polyurethanes.

4. Huntsman Corporation

Huntsman is renowned for its versatile polymeric polyol offerings, servicing a broad array of foam, adhesive, and elastomer markets. The company’s polyol grades span from commodity to highly specialized chemistries, including high‑functionality aromatic polyester polyols for rigid foam and low‑odor polyols for commercial automotive applications. Huntsman differentiates itself through agile production, enabling rapid scale‑up of niche products to meet customer specifications. Its advanced application labs in North America, Europe, and Asia provide robust technical support for complex formulation challenges. Huntsman’s commitment to sustainability is reflected in its development of recycled‑content and bio‑based polyols, aligning with global industry efforts toward circular economy practices.

5. Evonik Industries AG

Evonik specializes in high‑value polymeric polyols for specialty polyurethane applications, including elastomers, CASE systems, and high‑resilience foams. Its product portfolio emphasizes amine‑cured polyols, polyether carbonate polyols, and silane‑terminated polyether polyols, catering to demanding performance requirements such as impact resistance, low compression set, and chemical durability. Evonik’s deep expertise in functional group chemistry and process development supports the creation of unique polyol architectures for advanced applications like vibration damping and high‑temperature coatings. The company’s digital Twin Plant and process analytics initiatives enhance production efficiency and quality consistency, reinforcing Evonik’s position as a technology leader in the specialty polyol segment.

6. Wanhua Chemical Group Co., Ltd.

Wanhua is a dominant player in China’s polymeric polyol market, offering a wide array of polyether polyols and specialty grades for flexible foam, insulation, and CASE applications. The company’s vertically integrated production chain—from methyl diphenyl diisocyanate (MDI) to polyols—ensures cost competitiveness and supply security. Wanhua invests heavily in capacity expansion and process optimization, enabling it to meet rapidly growing domestic demand while expanding exports. Its collaboration with German partners and licensing of advanced MDI and PO technologies elevates product quality to global standards. Wanhua’s strategic focus on bio‑based polyol development aligns with China’s sustainability policies, positioning it for continued market leadership in Asia.

7. Mitsui Chemicals, Inc.

Mitsui Chemicals offers a diverse portfolio of polymeric polyols, with an emphasis on high‑functionality grades for rigid foam insulation and elastomeric applications. The company’s R&D efforts concentrate on improving thermal stability and mechanical properties through tailored molecular designs. Mitsui leverages its petrochemical upstream integration in Asia to secure feedstock supply and maintain competitive pricing. Its technical service centers collaborate with appliance and construction material manufacturers to co‑formulate energy‑efficient foam systems. With a global presence in Japan, Southeast Asia, and North America, Mitsui provides localized support, enabling swift customer response and fostering long‑term partnerships.

8. LG Chem Ltd.

LG Chem is a major South Korean producer of polymeric polyols, known for its high‑quality petrochemical integration and specialty polyol offerings. The company develops polyols for flexible foam, CASE, and elastomer markets, focusing on enhanced mechanical performance and compatibility with next‑generation diisocyanates. LG Chem’s investments in continuous manufacturing and advanced catalyst systems improve process yields and reduce energy consumption. Strategic collaborations with automotive and electronics OEMs drive application innovation, particularly in lightweight seating foams and protective coatings. LG Chem’s robust supply chain in Asia and strong technical support network underpin its competitive advantage in rapidly expanding regional markets.

9. PI Industries Ltd.

PI Industries is a leading Indian specialty chemicals company with a growing footprint in polymeric polyols. The company’s product range includes polyester and polyurethane polyols tailored for flexible and rigid foam applications. PI’s strength lies in its agility and customer focus, offering customized solutions for local formulators in the South Asian market. Its investments in multipurpose production plants enable flexible production volumes and rapid changeovers between grades. PI’s strategic partnerships with global licensors provide access to advanced polyol technologies, enhancing its product portfolio. The firm’s commitment to sustainability is reflected in its exploration of bio‑based polyols derived from agricultural by‑products, catering to regional preferences for green chemicals.

10. Stepan Company

Stepan Company specializes in surfactants and specialty polyols, with a strong presence in North America and Europe. Its polymeric polyols include polyether and polyester grades for flexible foam, CASE, and specialty elastomer applications. Stepan’s competitive advantage lies in its integrated R&D approach, combining surface‑active and polymer chemistry expertise to develop novel polyol structures with enhanced stability and processability. The company’s decentralized manufacturing network and focus on small‑to‑medium batch capabilities allow rapid responsiveness to customer needs. Stepan’s strategic investments in renewable feedstocks and waste‑derived building blocks position it well to meet growing demand for sustainable polyol solutions in global markets.

The report provides a detailed analysis of the Polymeric Polyol market across various regions, highlighting the unique market dynamics and growth opportunities in each region.

- US

- Canada

- Mexico

- UK

- Germany

- France

- Italy

- Russia

- Spain

- Switzerland

- Austria

- Belgium

- Rest of Europe

- China

- Japan

- South Korea

- Indonesia

- Vietnam

- Philippines

- Australia

- Thailand

- Singapore

- Rest of APAC

- UAE

- Saudi Arabia

- Egypt

- South Africa

- Israel

- Rest of MEA

- Brazil

- Argentina

- Rest of Latin America

>>> Need A Different Region Or Segment? Download PDF Sample

Key Takeaways

- The global Polymeric Polyol market is expected to grow significantly from 2024 to 2032, driven by technological advancements, increasing demand, and government investments in urbanization.

- The market is characterized by a diverse range of manufacturers, product types, and applications, catering to different consumer needs and preferences.

- Regional insights highlight the unique market dynamics and growth opportunities in various regions, including North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

- The competitive landscape features key players who have created a dynamic and diverse market environment through collaborations, mergers and acquisitions, and innovative product developments.

- Market trends such as technological advancements, sustainability, customization, and digital transformation are shaping the growth and development of the Polymeric Polyol market.

- Despite the positive outlook, the market faces challenges such as regulatory compliance, high initial investment costs, and economic uncertainties.

- The report provides comprehensive coverage of market size, market share, growth factors, and strategic insights to help businesses navigate the dynamic Polymeric Polyol market and achieve long-term success.

By leveraging the information provided in this report, businesses can develop effective strategies, address market challenges, and capitalize on growth opportunities to ensure sustainable growth and long-term success in the global Polymeric Polyol market.

- Introduction

- Objectives of the Study

- Market Definition

- Research Scope

- Currency

- Key Target Audience

- Research Methodology and Assumptions

- Executive Summary

- Premium Insights

- Porter’s Five Forces Analysis

- Value Chain Analysis

- Top Investment Pockets

- Industry Trends

- Market Dynamics

- Market Evaluation

- Drivers

- Restraints

- Opportunities

- Challenges

- Global Polymeric Polyol Market Analysis and Projection, By Companies

- Segment Overview

- Covestro

- BASF

- Cargill

- The Essential Chemical

- Stepan Company

- Bossco Industries

- SKC

- Huntsman

- Global Polymeric Polyol Market Analysis and Projection, By Type

- Segment Overview

- Medical Grade

- Industrial Grade

- Global Polymeric Polyol Market Analysis and Projection, By Application

- Segment Overview

- Drugs

- Chemical Products

- Other

- Global Polymeric Polyol Market Analysis and Projection, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Russia

- Spain

- Switzerland

- Austria

- Belgium

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Vietnam

- Philippines

- Australia

- Thailand

- Singapore

- Rest of APAC

- Middle East

- UAE

- Saudi Arabia

- Egypt

- South Africa

- Israel

- Rest of MEA

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Global Polymeric Polyol Market-Competitive Landscape

- Overview

- Market Share of Key Players in the Polymeric Polyol Market

- Global Company Market Share

- North America Company Market Share

- Europe Company Market Share

- APAC Company Market Share

- Competitive Situations and Trends

- Coverage Launches and Developments

- Partnerships, Collaborations, and Agreements

- Mergers & Acquisitions

- Expansions

- Company Profiles

- Covestro

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- BASF

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Cargill

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- The Essential Chemical

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Stepan Company

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Bossco Industries

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- SKC

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Huntsman

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

List of Table

- Drivers of Global Polymeric Polyol Market: Impact Analysis

- Restraints of Global Polymeric Polyol Market: Impact Analysis

- Global Polymeric Polyol Market, By Technology, 2023-2032(USD Billion)

- global Medical Grade, Polymeric Polyol Market, By Region, 2023-2032(USD Billion)

- global Industrial Grade, Polymeric Polyol Market, By Region, 2023-2032(USD Billion)

- global Drugs, Polymeric Polyol Market, By Region, 2023-2032(USD Billion)

- global Chemical Products, Polymeric Polyol Market, By Region, 2023-2032(USD Billion)

- global Other, Polymeric Polyol Market, By Region, 2023-2032(USD Billion)

List of Figures

- Global Polymeric Polyol Market Segmentation

- Polymeric Polyol Market: Research Methodology

- Market Size Estimation Methodology: Bottom-Up Approach

- Market Size Estimation Methodology: Top-down Approach

- Data Triangulation

- Porter’s Five Forces Analysis

- Value Chain Analysis

- Top investment pocket in the Polymeric Polyol Market

- Top Winning Strategies, 2023-2032

- Top Winning Strategies, By Development, 2023-2032(%)

- Top Winning Strategies, By Company, 2023-2032

- Moderate Bargaining power of Buyers

- Moderate Bargaining power of Suppliers

- Moderate Bargaining power of New Entrants

- Low threat of Substitution

- High Competitive Rivalry

- Restraint and Drivers: Polymeric Polyol Market

- Polymeric Polyol Market Segmentation, By Technology

- Polymeric Polyol Market For Live Attenuated, By Region, 2023-2033 ($ Billion)

- Global Polymeric Polyol Market, By Technology, 2023-2032(USD Billion)

- global Medical Grade, Polymeric Polyol Market, By Region, 2023-2032(USD Billion)

- global Industrial Grade, Polymeric Polyol Market, By Region, 2023-2032(USD Billion)

- global Drugs, Polymeric Polyol Market, By Region, 2023-2032(USD Billion)

- global Chemical Products, Polymeric Polyol Market, By Region, 2023-2032(USD Billion)

- global Other, Polymeric Polyol Market, By Region, 2023-2032(USD Billion)

- Covestro: Net Sales, 2023-2033 ($ Billion)

- Covestro: Revenue Share, By Segment, 2023 (%)

- Covestro: Revenue Share, By Region, 2023 (%)

- BASF: Net Sales, 2023-2033 ($ Billion)

- BASF: Revenue Share, By Segment, 2023 (%)

- BASF: Revenue Share, By Region, 2023 (%)

- Cargill: Net Sales, 2023-2033 ($ Billion)

- Cargill: Revenue Share, By Segment, 2023 (%)

- Cargill: Revenue Share, By Region, 2023 (%)

- The Essential Chemical: Net Sales, 2023-2033 ($ Billion)

- The Essential Chemical: Revenue Share, By Segment, 2023 (%)

- The Essential Chemical: Revenue Share, By Region, 2023 (%)

- Stepan Company: Net Sales, 2023-2033 ($ Billion)

- Stepan Company: Revenue Share, By Segment, 2023 (%)

- Stepan Company: Revenue Share, By Region, 2023 (%)

- Bossco Industries: Net Sales, 2023-2033 ($ Billion)

- Bossco Industries: Revenue Share, By Segment, 2023 (%)

- Bossco Industries: Revenue Share, By Region, 2023 (%)

- SKC: Net Sales, 2023-2033 ($ Billion)

- SKC: Revenue Share, By Segment, 2023 (%)

- SKC: Revenue Share, By Region, 2023 (%)

- Huntsman: Net Sales, 2023-2033 ($ Billion)

- Huntsman: Revenue Share, By Segment, 2023 (%)

- Huntsman: Revenue Share, By Region, 2023 (%)

Infinitive Data Research provides comprehensive market research, offering in-depth market analysis to help companies understand their target market and industry competition. This research predicts the market acceptance of your brand and products, ensuring informed decision-making for business success.

Competitor Analysis in the Polymeric Polyol Industry

Conducting a competitor analysis involves identifying competitors within the Polymeric Polyol industry and studying their various marketing strategies. This comparative data allows you to assess your company's strengths and weaknesses relative to competitors, providing insights to enhance your market position.

Importance of Continuous Market Research

Consistently conducting market research is essential for minimizing risk at every stage of business operations. Polymeric Polyol market research enables you to collect qualitative and quantitative data, which, when properly analyzed, leads to wise decisions that align with user and customer needs. Below are some crucial lessons learned through the Polymeric Polyol market research process:

Key Dimensions of Polymeric Polyol Market Analysis

- Trend and Pattern Identification: Analyzing data to spot market trends and patterns.

- Pricing Analysis: Assessing keyword pricing strategies.

- Actionable Insights: Implementing insights derived from data analysis.

- Market Potential: Evaluating the potential of the Polymeric Polyol market.

- Competitor Analysis: Studying competitors' strategies and performance.

- Location Analysis: Assessing optimal locations for market penetration.

- Distribution Channels Analysis: Evaluating the effectiveness of distribution channels.

- Market Size and Growth Rate: Measuring market size and growth potential.

- Market Profitability: Assessing profitability prospects.

- Key Success Factors: Identifying critical factors for success.

- Cost Structure: Understanding the cost structure within the Polymeric Polyol industry.

Target Audience for the Report

This report is valuable for a diverse audience, including:

- Polymeric Polyol Market Manufacturers: To understand market dynamics and enhance production strategies.

- Investors and Financing Companies: To assess investment opportunities and risks.

- Polymeric Polyol Market Suppliers: To identify market demands and supply chain efficiencies.

Necessity of the Report

Making Crucial Business Decisions

Understanding the Polymeric Polyol market, competition, and industry landscape is vital for making informed business decisions. Without current and relevant market research, decisions may be based on outdated or irrelevant information, potentially harming the business.

Securing Investment Funds

Attracting investors requires demonstrating thorough market research. Investors need assurance that you understand the sector, current and potential competition, and whether your idea addresses a market need.

Identifying New Business Opportunities

Polymeric Polyol market research goes beyond understanding trends and consumer behavior. It identifies new revenue streams and opportunities for business pivots. These insights can lead to strategic changes in the business model, promoting growth and adapting to market challenges.

Avoiding Business Failures

Market research also plays a crucial role in risk mitigation. It can reveal when not to pursue certain actions, saving the company from potential losses in revenue, brand image, and more. This proactive approach is often overlooked but is essential for long-term success.

Conclusion

Infinitive Data Research's comprehensive Polymeric Polyol market research provides critical insights for making solid business decisions, securing investments, identifying new opportunities, and avoiding potential failures. Understanding market dynamics through continuous research ensures your company remains competitive and thrives in the Polymeric Polyol industry.