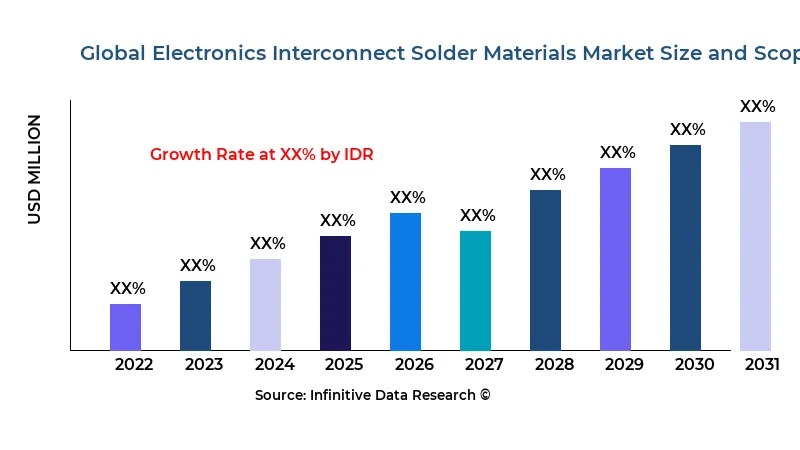

Electronics Interconnect Solder Materials Market Growth CAGR Overview

According to research by Infinitive Data Research, the global Electronics Interconnect Solder Materials Market size was valued at USD 4.6 Bln (billion) in 2024 and is Calculated to reach USD 5.5 Bln (billion) by the end of 2032, growing at an anticipated compound annual growth rate (CAGR) of 6.8% during the forecast period 2024 to 2032. This projected growth is driven by its increasing adoption across Semiconductors industries such as SMT Assembly, Semiconductor PackagingThe electronics interconnect solder materials market is experiencing transformative shifts driven by rapid advancements in electronic design and manufacturing practices. The growing demand for high-speed and high-density electronic assemblies has pushed manufacturers to innovate materials that offer superior conductivity and mechanical stability. This evolution is often fueled by the need to support the miniaturization of components, which in turn, has led to a rethinking of traditional solder formulations. As the industry moves toward automation and higher yield processes, manufacturers are required to adhere to stricter quality and environmental standards, thereby intensifying research investments.

A key aspect affecting market dynamics is the regulatory landscape that mandates the use of lead-free and environmentally sustainable soldering materials. This pressure from regulatory authorities across North America, Europe, and parts of Asia has compelled companies to adopt and invest in new technologies that minimize environmental impact without compromising product performance. The transition to lead-free alternatives has spurred significant research and technological breakthroughs, offering improved reliability in high-performance interconnect applications. This dual focus on compliance and performance is redefining competitive strategies in the market, thereby opening up new avenues for growth.

Another critical factor influencing market dynamics is the accelerated pace of product development in consumer electronics and industrial automation. Manufacturers are striving to develop solder materials that not only meet stringent reliability benchmarks but also offer consistent performance amidst frequent temperature cycling and mechanical stresses. The increasing demand for smaller, lighter, and more powerful electronic devices is driving innovation in solder materials that can sustain complex assembly requirements. These developments are essential to meet the rapid prototyping and production cycles demanded by the modern electronics ecosystem, ultimately reshaping the competitive landscape.

Global supply chain integration and shifting trade dynamics are also playing a pivotal role in the market. The need for a reliable and agile supply chain has led to strategic collaborations among manufacturers, distributors, and technology providers. This integrated approach facilitates the faster adoption of cutting-edge technologies and helps manufacturers swiftly adjust to volatile raw material costs and evolving regulatory mandates. As technology cycles become shorter, companies that can streamline production processes and deliver high-quality solder materials on time gain a considerable competitive advantage in the market.

>>> Understand The Key Trends Shaping This Market:- Download PDF Sample

Electronics Interconnect Solder Materials Market Growth Factors

Innovation in solder materials design is a major growth driver in the electronics interconnect sector. Manufacturers are increasingly emphasizing the development of solder compositions that offer enhanced thermal resistance, mechanical durability, and improved electrical conductivity to support next-generation electronic devices. The growing demand for miniaturized components, particularly in the automotive and mobile electronics sectors, reinforces the need for solder materials that can withstand extreme operational conditions. Continuous innovation is not only central to product differentiation but also critical to meeting global quality and environmental standards.

The push towards lead-free solutions has markedly accelerated market growth. As environmental regulations become increasingly stringent, the industry has responded by investing heavily in the development of eco-friendly solder alternatives. These investments have resulted in new alloys with improved performance characteristics, making them highly sought-after by manufacturers in both mature and emerging markets. The gradual regulatory phase-out of lead-based solders and the corresponding shift to non-toxic alternatives has resulted in a dynamic reallocation of R&D resources, fostering an innovation-rich environment that supports robust market growth.

Rising consumer demands for durable and high-performance electronic products also underpin market expansion. In an era where devices are expected to deliver consistent performance over extended periods, the reliability of interconnect solder materials is of paramount importance. With electronics becoming central to both consumer lifestyles and industrial operations, the market is witnessing a surge in demand for materials that offer longevity, stability, and resistance to electrical and thermal stress. This trend is particularly pronounced in sectors such as data centers, telecommunications, and automotive electronics, where the failure of solder joints can have far-reaching consequences.

Market growth is further enhanced by the global expansion of electronics manufacturing, particularly in fast-growing economies. Manufacturers are scaling up production capabilities to meet the demand for advanced electronic components, which in turn is driving the need for high-quality soldering materials. This expansion is coupled with the continuous technological evolution within the electronics industry, which necessitates constant improvements in solder materials to maintain competitive advantages. Companies that successfully align their product development with the global demand for innovation and reliability are therefore well poised for sustainable growth.

Market Analysis By Competitors

- Accurus

- AIM

- Alent (Alpha)

- DS HiMetal

- Henkel

- Indium

- Inventec

- KAWADA

- Kester(ITW)

- KOKI

- MKE

- Nihon Superior

- Nippon Micrometal

- PMTC

- Senju Metal

- Shanghai hiking solder material

- Shenmao Technology

- Shenzhen Bright

- Tamura

- Tongfang Tech

- Yashida

- YCTC

- Yong An

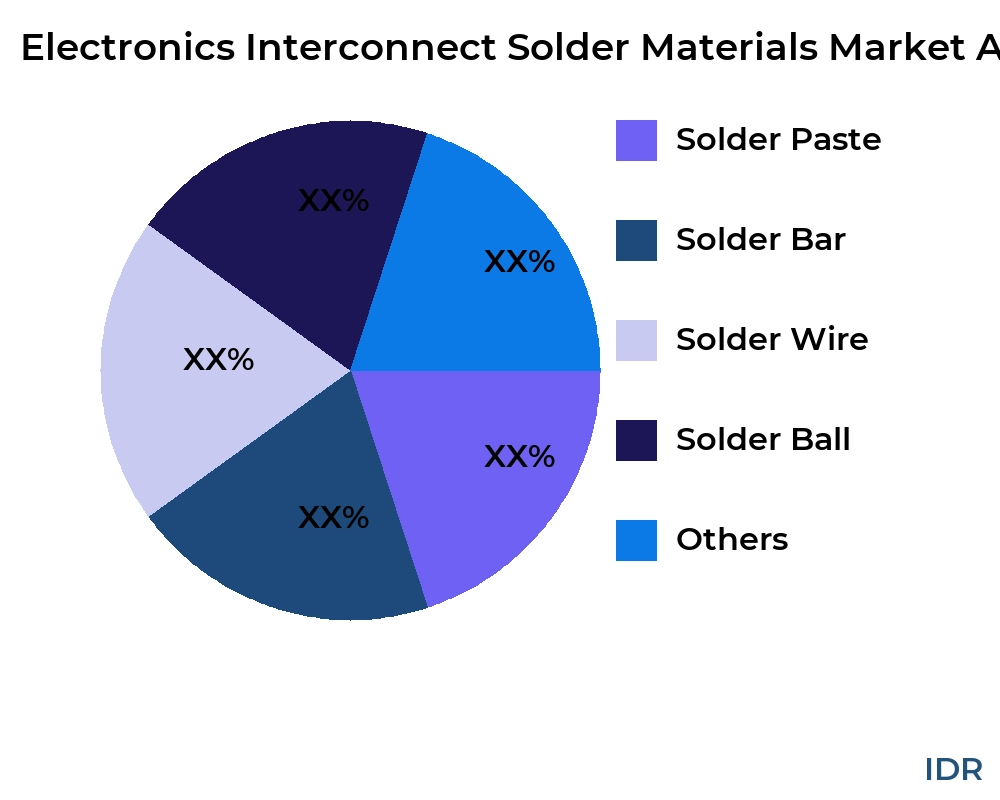

By Product Type

- Solder Paste

- Solder Bar

- Solder Wire

- Solder Ball

- Others

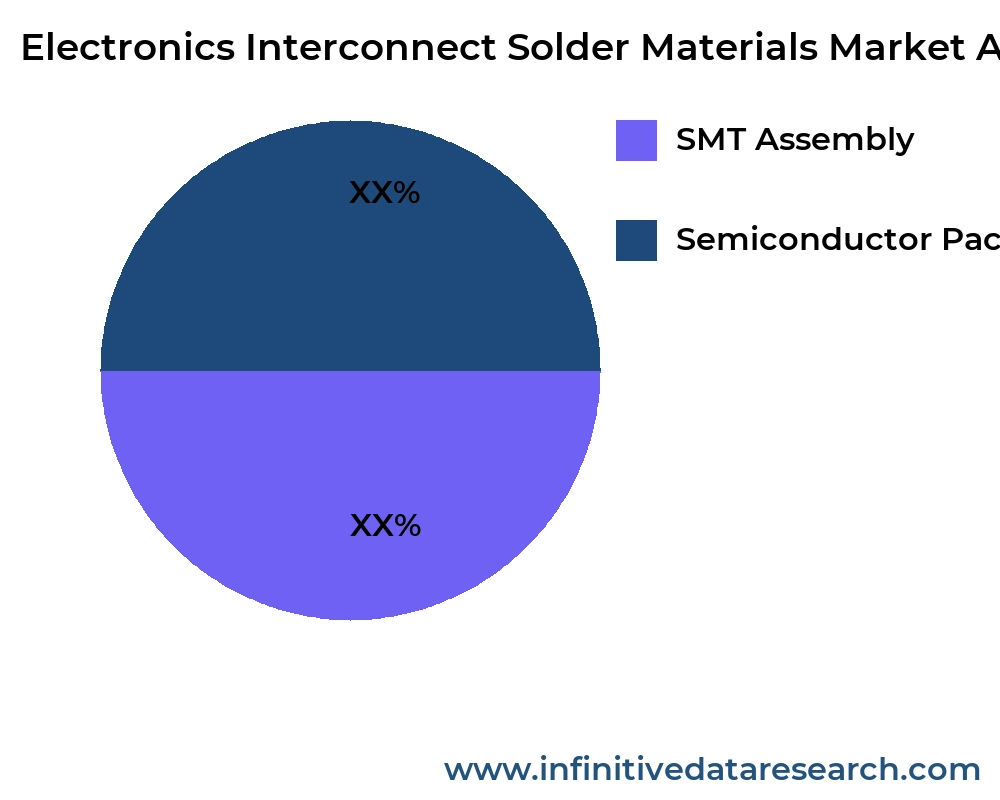

By Application

- SMT Assembly

- Semiconductor Packaging

>>> Understand The Key Trends Shaping This Market:- Understand The Key Trends Shaping This Market:-

Electronics Interconnect Solder Materials Market Segment Analysis

Distribution ChannelThe distribution channel for electronics interconnect solder materials comprises direct sales, specialized distributors, and e-commerce platforms, each playing a vital role in market accessibility and customer service. Direct sales channels facilitate close technical interaction and customized solutions for large-scale clients and OEMs. Specialized distributors provide comprehensive regional coverage, ensuring the availability of high-quality solder materials to manufacturers in various sectors. The digital transformation in the industry has also seen a surge in online platforms that streamline order processing, inventory management, and customer engagement, thereby enhancing the overall efficiency of the supply chain.

CompatibilityCompatibility is a defining criterion in the electronics interconnect solder materials market, given the diverse array of substrates and semiconductor components employed in modern electronics. Manufacturers invest in extensive compatibility testing to ensure that solder materials can reliably connect components under varying operational conditions. The ability of solder materials to meet the demands of both traditional and next-generation electronic devices is critical. This segment is characterized by a continuous drive to improve adhesion properties and prevent issues such as tin whiskering, ensuring that compatibility extends seamlessly across different materials and applications. As a result, the market is evolving to support the rapid integration of advanced interconnect technologies.

PricePrice remains a crucial factor in shaping market trends, as cost pressures and raw material volatility affect the competitive landscape of solder materials. The pricing strategies in this segment reflect a balance between affordability and performance, with companies offering a range of products designed to meet different customer budgets. Manufacturers are engaged in continuous cost-reduction initiatives without compromising product quality, which is especially important for high-volume electronics production. The competitive environment forces suppliers to innovate not just technologically but also in terms of operational efficiency and pricing models. This pricing dynamic ensures that even as product performance improves, cost-effectiveness remains within the central focus of market strategies.

Product TypeThe product type segment for electronics interconnect solder materials is vast, encompassing traditional solder alloys and advanced, lead-free formulations. This diversity caters to a broad spectrum of applications from low-power consumer electronics to high-end industrial and automotive systems. Manufacturers are continuously refining product types to address technical challenges such as thermal fatigue, electromigration, and mechanical stresses that are inherent in densely packed electronic assemblies. The ongoing development of new solder compositions designed specifically for high-performance and miniaturized device applications is reflective of the market’s commitment to innovation and quality assurance. Such product differentiation allows companies to target various customer segments with specialized, high-value offerings.

| REPORT ATTRIBUTES | DETAILS |

|---|---|

| Study Period |

2019-2032 |

| Base Year |

2023 |

| Forecast Period |

2024-2032 |

| Historical Period |

2019-2022 |

| Unit |

Value (USD Billion) |

| Key Companies Profiled |

Accurus, AIM, Alent (Alpha), DS HiMetal, Henkel, Indium, Inventec, KAWADA, Kester(ITW), KOKI, MKE, Nihon Superior, Nippon Micrometal, PMTC, Senju Metal, Shanghai hiking solder material, Shenmao Technology, Shenzhen Bright, Tamura, Tongfang Tech, Yashida, YCTC, Yong An |

| Segments Covered |

By Product |

| Customization Scope |

Free report customization (equivalent to up to 3 analyst working days) with purchase. Addition or alteration to country, regional and segment scope |

>>> Overview of Market Analysis:- Download PDF Sample

Electronics Interconnect Solder Materials Market Regional Analysis

North America continues to be a significant market for electronics interconnect solder materials, driven by high-end manufacturing and strict quality standards. The region’s emphasis on research and development combined with stringent regulatory measures has made it a hub for adopting advanced interconnect solutions. Manufacturers in North America benefit from a well-developed supply chain, which in turn supports rapid innovation and the swift rollout of next-generation solder materials. This region’s competitive market environment is bolstered by significant investments in high-tech industries and robust consumer demand for high-performance electronic products.

In Europe, the electronics interconnect solder materials market is shaped by rigorous environmental policies and a strong focus on sustainability. European manufacturers have rapidly adapted to lead-free technologies, responding to both regulatory mandates and customer demand for environmentally responsible products. The region’s close integration of academic research, technical innovation, and industrial expertise has fostered a landscape where product quality and reliability are paramount. Moreover, strong collaboration among industry players and governments supports continued investments in sustainable manufacturing processes, positioning Europe as an innovative leader in the field.

The Asia-Pacific region represents one of the fastest-growing markets for electronics interconnect solder materials owing to its expanding electronics manufacturing base and rapid industrialization. Countries in this region have seen substantial increases in production volumes driven by high-tech sectors such as consumer electronics, automotive, and telecommunications. Manufacturers in Asia-Pacific are leveraging advanced production techniques and cost-effective raw materials to capture significant market share. The region benefits from a large and skilled workforce, growing domestic demand, and proactive investments in technological upgrades, all contributing to its dynamic market growth trajectory.

Emerging markets in Latin America and the Middle East are gradually establishing themselves as promising territories for electronics interconnect solder materials. Driven by the modernization of manufacturing infrastructure and increasing demand for high-tech electronic applications, these regions are witnessing a steady influx of advanced solder materials. Local manufacturers are increasingly integrating global best practices, while partnerships with international suppliers help enhance the quality and availability of products. Government initiatives aimed at industrial development and technology adoption further underscore the long-term growth prospects of these nascent markets.

global Electronics Interconnect Solder Materials market revenue (usd million) comparison by players 2024-2032

| Company/players | 2021 | 2022 | 2023 | 2024 | ... | (2032) |

|---|---|---|---|---|---|---|

| Accurus | XX | XX | XX | XX | XX | XX |

| AIM | XX | XX | XX | XX | XX | XX |

| Alent (Alpha) | XX | XX | XX | XX | XX | XX |

| DS HiMetal | XX | XX | XX | XX | XX | XX |

| Henkel | XX | XX | XX | XX | XX | XX |

| Indium | XX | XX | XX | XX | XX | XX |

| Inventec | XX | XX | XX | XX | XX | XX |

| KAWADA | XX | XX | XX | XX | XX | XX |

| Kester(ITW) | XX | XX | XX | XX | XX | XX |

| KOKI | XX | XX | XX | XX | XX | XX |

| MKE | XX | XX | XX | XX | XX | XX |

| Nihon Superior | XX | XX | XX | XX | XX | XX |

| Nippon Micrometal | XX | XX | XX | XX | XX | XX |

| PMTC | XX | XX | XX | XX | XX | XX |

| Senju Metal | XX | XX | XX | XX | XX | XX |

| Shanghai hiking solder material | XX | XX | XX | XX | XX | XX |

| Shenmao Technology | XX | XX | XX | XX | XX | XX |

| Shenzhen Bright | XX | XX | XX | XX | XX | XX |

| Tamura | XX | XX | XX | XX | XX | XX |

| Tongfang Tech | XX | XX | XX | XX | XX | XX |

| Yashida | XX | XX | XX | XX | XX | XX |

| YCTC | XX | XX | XX | XX | XX | XX |

| Yong An | XX | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX | XX |

global Electronics Interconnect Solder Materials market revenue (usd million) comparison by product type 2024-2032

Product Type

2023

2024

...

2032

CAGR%(2024-32)

Solder Paste

XX

XX

XX

XX

XX

Solder Bar

XX

XX

XX

XX

XX

Solder Wire

XX

XX

XX

XX

XX

Solder Ball

XX

XX

XX

XX

XX

Others

XX

XX

XX

XX

XX

Total

XX

XX

XX

XX

XX

| Product Type | 2023 | 2024 | ... | 2032 | CAGR%(2024-32) |

|---|---|---|---|---|---|

| Solder Paste | XX | XX | XX | XX | XX |

| Solder Bar | XX | XX | XX | XX | XX |

| Solder Wire | XX | XX | XX | XX | XX |

| Solder Ball | XX | XX | XX | XX | XX |

| Others | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX |

global Electronics Interconnect Solder Materials market revenue (usd million) comparison by application 2024-2032

Application

2023

2024

...

2032

CAGR%(2024-32)

SMT Assembly

XX

XX

XX

XX

XX

Semiconductor Packaging

XX

XX

XX

XX

XX

Total

XX

XX

XX

XX

XX

| Application | 2023 | 2024 | ... | 2032 | CAGR%(2024-32) |

|---|---|---|---|---|---|

| SMT Assembly | XX | XX | XX | XX | XX |

| Semiconductor Packaging | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX |

>>> Market Understand Through Graph And Chart:- Download PDF Sample

Electronics Interconnect Solder Materials Market Competitive Insights

The competitive landscape in the electronics interconnect solder materials market is marked by robust investments in research and product innovation. Leading companies are focusing on developing new alloys that meet the stringent performance demands of modern electronic assemblies while complying with environmental regulations. The interplay of cost pressures and technical challenges such as miniaturization has spurred a wave of innovation that enhances product reliability and performance. Major players are actively engaging in strategic partnerships to leverage specialized capabilities and tap into new regional markets.

In a market defined by rapid technological change, competitive differentiation largely depends on the ability to innovate and meet evolving customer requirements. Companies that prioritize technological advancements in lead-free and high-performance solder formulations are able to differentiate themselves from traditional competitors. Such innovation not only meets industry demands but also opens avenues in niche markets that require customized material solutions. The focus on quality improvement and the adoption of state-of-the-art manufacturing processes are key factors that enhance market competitiveness in an environment marked by high technological standards.

As the market matures, consolidation through mergers and acquisitions has become a common strategic approach for companies to enhance their competitive positioning. Mergers allow companies to combine resources and technical expertise, creating robust production capacities and broad product portfolios. In this evolving landscape, innovation, cost-efficiency, and quality assurance are the principal drivers of competitive success. Market participants continuously refine their strategies to address the dual challenges of regulatory compliance and increased consumer expectations, resulting in dynamic competitive activity that fuels further market evolution.

The competitive dynamics in this sector are further accentuated by the growing emphasis on sustainability and environmental stewardship. Industry leaders that integrate eco-friendly manufacturing practices and focus on green chemistry are increasingly capturing market share by appealing to environmentally conscious customers. The competition extends beyond traditional performance metrics to include social responsibility and sustainability as key components of corporate strategy. This broader focus on responsible innovation and operational efficiency continues to redefine competitive benchmarks across the industry.

Electronics Interconnect Solder Materials Market Competitors

United States

• SolderTech Innovations

• Elite Alloy Systems

• Advanced Interconnect Materials

• ProSolder Solutions

• NextGen Solder Corp

Germany

• EuroInterconnect Materials

• Technosolder AG

• Precision Alloy Innovations

• German Solder Dynamics

• Interconnect Solder GmbH

Japan

• Nippon Interconnect Solder

• Japan Alloy Innovations

• HighTech Solder Japan

• Precision Interconnect Corp

• SolderLink Technologies

China

• Eastern Interconnect Alloys

• DragonTech Solder Materials

• Sino Interconnect Innovations

• China Precision Soldering

• Superior Alloy Systems

South Korea

• Korea Interconnect Solder

• HanTech Alloy Solutions

• Seoul Solder Dynamics

• K-Solder Innovations

• Interconnect Korea Corp

India

• India Interconnect Materials

• Bharat Advanced Soldering

• Precision Alloy India

• SolderTech Innovations

• Mumbai Interconnect Solder

Electronics Interconnect Solder Materials Market Top Competitors

SolderTech Innovations (United States)

SolderTech Innovations is recognized as a premier player in the electronics interconnect solder materials sector with a long history of product excellence. The company continuously invests in state-of-the-art production facilities that adhere to rigorous international quality standards. Its focus on developing lead-free and high-performance solder materials has set industry benchmarks and attracted a wide range of clientele across technology sectors. SolderTech Innovations is distinguished by its innovative R&D processes, enabling rapid adaptation to market trends. With a strong global distribution network, it caters to diverse customer needs, solidifying its leadership in high-reliability solder materials. The company’s forward-thinking approach consistently enhances its reputation and market share in key regions.

Elite Alloy Systems (United States)

Elite Alloy Systems has established its strong presence as a competitive leader through continuous innovation and reliability in its product offerings. The company has built a reputation for delivering advanced solder formulations that meet the increasingly stringent specifications of modern electronic systems. Its emphasis on research-driven development allows it to pioneer new technologies that significantly improve solder joint reliability. Elite Alloy Systems’ comprehensive quality management system and robust supply chain network are cornerstones of its market strategy. The company actively engages in partnerships with key industry players to further integrate advanced technologies into its products. Its commitment to sustainable manufacturing practices reinforces its strong position across the highly competitive electronics interconnect market.

Advanced Interconnect Materials (United States)

Advanced Interconnect Materials has rapidly become synonymous with high quality and technical excellence in the electronics interconnect solder materials arena. Through continuous innovation and a steadfast commitment to performance improvement, the company has garnered respect from major OEMs and technology providers. Advanced Interconnect Materials invests substantially in R&D, ensuring that its products meet the latest technological demands and environmental regulations. Its streamlined manufacturing operations and strategically positioned distribution channels enable consistent delivery of high-performance solder solutions globally. The company’s integrated approach to design, manufacturing, and customer service further strengthens its market position. This comprehensive strategy has helped Advanced Interconnect Materials secure strong footholds in both domestic and international markets.

ProSolder Solutions (United States)

ProSolder Solutions is a dynamic competitor well known for its innovative approach to enhancing solder technology for interconnect applications. The company has focused on developing advanced, environmentally friendly solder formulations that meet cutting-edge industry requirements. Consistent product quality and excellent customer service have allowed ProSolder Solutions to build long-term relationships with leading electronics manufacturers. The company operates an efficient production process coupled with comprehensive R&D initiatives that drive continuous improvement. Its expansive product portfolio is tailored to the needs of high-density electronic assemblies and varied industrial applications. This strategic emphasis on quality and technological leadership solidifies its competitive stance in the global market.

NextGen Solder Corp (United States)

NextGen Solder Corp has emerged as a forward-thinking leader, driven by continuous investment in next-generation soldering solutions that cater to the evolving electronics industry. The company’s portfolio is noted for its cutting-edge technology, particularly its advanced lead-free solder variants designed for high-reliability applications. NextGen Solder Corp leverages innovative R&D to rapidly iterate and optimize new product offerings that meet rigorous performance standards. Its integrated supply chain and strong regional partnerships ensure timely delivery and consistent quality across diverse markets. The company’s commitment to sustainability, combined with a focus on customer-centric product innovation, reinforces its strong market reputation. As a trendsetter in the industry, NextGen Solder Corp consistently adapts to shifting market demands while maintaining robust growth.

Japan Alloy Innovations (Japan)

Japan Alloy Innovations has built a formidable presence in the electronics interconnect solder materials market through its unwavering focus on quality, reliability, and technological innovation. The company leverages Japan’s rich heritage of precision engineering to develop solder materials that deliver outstanding performance under challenging conditions. Investments in R&D are a key aspect of their strategy, resulting in innovative products designed for high-speed electronic assemblies. Japan Alloy Innovations benefits from an efficient production process that integrates automation and quality assurance. Strategic collaborations with leading electronics manufacturers further enhance their market presence. This commitment to excellence has earned the company a strong reputation both domestically and internationally, positioning it as a top-tier competitor in advanced solder technology.

HighTech Solder Japan (Japan)

HighTech Solder Japan distinguishes itself by focusing on high-precision solder materials that cater to the advanced technological requirements of modern electronics. The company continuously develops innovative solutions that address issues related to thermal stability, conductivity, and mechanical robustness. Its commitment to rigorous quality control and rapid technological adaptation makes HighTech Solder Japan a preferred supplier for high-end manufacturers. Significant investments in research facilities ensure that its products remain at the cutting edge of innovation. The company’s market strategy emphasizes sustainable practices and long-term product reliability, which resonates well with its global customer base. As a result, HighTech Solder Japan has secured a leading role in the industry’s value chain.

Precision Interconnect Corp (Japan)

Precision Interconnect Corp is widely recognized for its commitment to delivering high-performance solder materials and unmatched reliability in a competitive market. With a focus on precision engineering and advanced material science, the company continually refines its products to meet the evolving demands of high-density electronic assemblies. Its rigorous testing protocols and adherence to international standards have set new benchmarks in solder performance, particularly for mission-critical applications. Precision Interconnect Corp is dedicated to environmental sustainability, which is reflected in its comprehensive approach to lead-free technologies. The company’s strong regional partnerships and an expanding global footprint further reinforce its status as a market leader. This consistent approach to quality and performance has cemented its reputation among industry stakeholders.

Eastern Interconnect Alloys (China)

Eastern Interconnect Alloys has established itself as a fast-growing player in the Asia-Pacific market, focusing on advanced solder formulations that power a wide range of electronic applications. The company’s innovation-driven strategy has led to the successful introduction of several high-performance products that address specific industrial challenges. With a robust manufacturing platform, Eastern Interconnect Alloys emphasizes rapid product development and reliable supply chain management. Their products are distinguished by their strong adhesion properties and resistance to thermal and mechanical stresses, making them an ideal choice for modern electronics. The company’s competitive pricing strategies and continuous quality improvements have allowed it to capture a significant share of both domestic and international markets. Eastern Interconnect Alloys’ commitment to excellence continues to drive its expansion and position it as a major competitor in the solder materials industry.

DragonTech Solder Materials (China)

DragonTech Solder Materials has rapidly advanced in the competitive landscape through its focus on innovative product development and technological adaptation. The company is known for its commitment to delivering high-quality solder materials that meet the exacting standards of next-generation electronic devices. DragonTech invests heavily in research and development to continuously improve the performance, reliability, and environmental compatibility of its products. Its strategic production framework is supported by modern manufacturing facilities that ensure high throughput and cost efficiency. The company’s focus on customer-centric solutions and comprehensive after-sales service has strengthened its long-term partnerships with electronics manufacturers. This proactive approach to market demands has positioned DragonTech Solder Materials as a key player in the electronics interconnect sector.

The report provides a detailed analysis of the Electronics Interconnect Solder Materials market across various regions, highlighting the unique market dynamics and growth opportunities in each region.

- US

- Canada

- Mexico

- UK

- Germany

- France

- Italy

- Russia

- Spain

- Switzerland

- Austria

- Belgium

- Rest of Europe

- China

- Japan

- South Korea

- Indonesia

- Vietnam

- Philippines

- Australia

- Thailand

- Singapore

- Rest of APAC

- UAE

- Saudi Arabia

- Egypt

- South Africa

- Israel

- Rest of MEA

- Brazil

- Argentina

- Rest of Latin America

>>> Need A Different Region Or Segment? Download PDF Sample

Key Takeaways

- The global Electronics Interconnect Solder Materials market is expected to grow significantly from 2024 to 2032, driven by technological advancements, increasing demand, and government investments in urbanization.

- The market is characterized by a diverse range of manufacturers, product types, and applications, catering to different consumer needs and preferences.

- Regional insights highlight the unique market dynamics and growth opportunities in various regions, including North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

- The competitive landscape features key players who have created a dynamic and diverse market environment through collaborations, mergers and acquisitions, and innovative product developments.

- Market trends such as technological advancements, sustainability, customization, and digital transformation are shaping the growth and development of the Electronics Interconnect Solder Materials market.

- Despite the positive outlook, the market faces challenges such as regulatory compliance, high initial investment costs, and economic uncertainties.

- The report provides comprehensive coverage of market size, market share, growth factors, and strategic insights to help businesses navigate the dynamic Electronics Interconnect Solder Materials market and achieve long-term success.

By leveraging the information provided in this report, businesses can develop effective strategies, address market challenges, and capitalize on growth opportunities to ensure sustainable growth and long-term success in the global Electronics Interconnect Solder Materials market.

- Introduction

- Objectives of the Study

- Market Definition

- Research Scope

- Currency

- Key Target Audience

- Research Methodology and Assumptions

- Executive Summary

- Premium Insights

- Porter’s Five Forces Analysis

- Value Chain Analysis

- Top Investment Pockets

- Industry Trends

- Market Dynamics

- Market Evaluation

- Drivers

- Restraints

- Opportunities

- Challenges

- Global Electronics Interconnect Solder Materials Market Analysis and Projection, By Companies

- Segment Overview

- Accurus

- AIM

- Alent (Alpha)

- DS HiMetal

- Henkel

- Indium

- Inventec

- KAWADA

- Kester(ITW)

- KOKI

- MKE

- Nihon Superior

- Nippon Micrometal

- PMTC

- Senju Metal

- Shanghai hiking solder material

- Shenmao Technology

- Shenzhen Bright

- Tamura

- Tongfang Tech

- Yashida

- YCTC

- Yong An

- Global Electronics Interconnect Solder Materials Market Analysis and Projection, By Type

- Segment Overview

- Solder Paste

- Solder Bar

- Solder Wire

- Solder Ball

- Others

- Global Electronics Interconnect Solder Materials Market Analysis and Projection, By Application

- Segment Overview

- SMT Assembly

- Semiconductor Packaging

- Global Electronics Interconnect Solder Materials Market Analysis and Projection, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Russia

- Spain

- Switzerland

- Austria

- Belgium

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Vietnam

- Philippines

- Australia

- Thailand

- Singapore

- Rest of APAC

- Middle East

- UAE

- Saudi Arabia

- Egypt

- South Africa

- Israel

- Rest of MEA

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Global Electronics Interconnect Solder Materials Market-Competitive Landscape

- Overview

- Market Share of Key Players in the Electronics Interconnect Solder Materials Market

- Global Company Market Share

- North America Company Market Share

- Europe Company Market Share

- APAC Company Market Share

- Competitive Situations and Trends

- Coverage Launches and Developments

- Partnerships, Collaborations, and Agreements

- Mergers & Acquisitions

- Expansions

- Company Profiles

- Accurus

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- AIM

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Alent (Alpha)

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- DS HiMetal

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Henkel

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Indium

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Inventec

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- KAWADA

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Kester(ITW)

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- KOKI

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- MKE

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Nihon Superior

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Nippon Micrometal

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- PMTC

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Senju Metal

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Shanghai hiking solder material

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Shenmao Technology

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Shenzhen Bright

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Tamura

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Tongfang Tech

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Yashida

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- YCTC

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Yong An

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

List of Table

- Drivers of Global Electronics Interconnect Solder Materials Market: Impact Analysis

- Restraints of Global Electronics Interconnect Solder Materials Market: Impact Analysis

- Global Electronics Interconnect Solder Materials Market, By Technology, 2023-2032(USD Billion)

- global Solder Paste, Electronics Interconnect Solder Materials Market, By Region, 2023-2032(USD Billion)

- global Solder Bar, Electronics Interconnect Solder Materials Market, By Region, 2023-2032(USD Billion)

- global Solder Wire, Electronics Interconnect Solder Materials Market, By Region, 2023-2032(USD Billion)

- global Solder Ball, Electronics Interconnect Solder Materials Market, By Region, 2023-2032(USD Billion)

- global Others, Electronics Interconnect Solder Materials Market, By Region, 2023-2032(USD Billion)

- global SMT Assembly, Electronics Interconnect Solder Materials Market, By Region, 2023-2032(USD Billion)

- global Semiconductor Packaging, Electronics Interconnect Solder Materials Market, By Region, 2023-2032(USD Billion)

List of Figures

- Global Electronics Interconnect Solder Materials Market Segmentation

- Electronics Interconnect Solder Materials Market: Research Methodology

- Market Size Estimation Methodology: Bottom-Up Approach

- Market Size Estimation Methodology: Top-down Approach

- Data Triangulation

- Porter’s Five Forces Analysis

- Value Chain Analysis

- Top investment pocket in the Electronics Interconnect Solder Materials Market

- Top Winning Strategies, 2023-2032

- Top Winning Strategies, By Development, 2023-2032(%)

- Top Winning Strategies, By Company, 2023-2032

- Moderate Bargaining power of Buyers

- Moderate Bargaining power of Suppliers

- Moderate Bargaining power of New Entrants

- Low threat of Substitution

- High Competitive Rivalry

- Restraint and Drivers: Electronics Interconnect Solder Materials Market

- Electronics Interconnect Solder Materials Market Segmentation, By Technology

- Electronics Interconnect Solder Materials Market For Live Attenuated, By Region, 2023-2033 ($ Billion)

- Global Electronics Interconnect Solder Materials Market, By Technology, 2023-2032(USD Billion)

- global Solder Paste, Electronics Interconnect Solder Materials Market, By Region, 2023-2032(USD Billion)

- global Solder Bar, Electronics Interconnect Solder Materials Market, By Region, 2023-2032(USD Billion)

- global Solder Wire, Electronics Interconnect Solder Materials Market, By Region, 2023-2032(USD Billion)

- global Solder Ball, Electronics Interconnect Solder Materials Market, By Region, 2023-2032(USD Billion)

- global Others, Electronics Interconnect Solder Materials Market, By Region, 2023-2032(USD Billion)

- global SMT Assembly, Electronics Interconnect Solder Materials Market, By Region, 2023-2032(USD Billion)

- global Semiconductor Packaging, Electronics Interconnect Solder Materials Market, By Region, 2023-2032(USD Billion)

- Accurus: Net Sales, 2023-2033 ($ Billion)

- Accurus: Revenue Share, By Segment, 2023 (%)

- Accurus: Revenue Share, By Region, 2023 (%)

- AIM: Net Sales, 2023-2033 ($ Billion)

- AIM: Revenue Share, By Segment, 2023 (%)

- AIM: Revenue Share, By Region, 2023 (%)

- Alent (Alpha): Net Sales, 2023-2033 ($ Billion)

- Alent (Alpha): Revenue Share, By Segment, 2023 (%)

- Alent (Alpha): Revenue Share, By Region, 2023 (%)

- DS HiMetal: Net Sales, 2023-2033 ($ Billion)

- DS HiMetal: Revenue Share, By Segment, 2023 (%)

- DS HiMetal: Revenue Share, By Region, 2023 (%)

- Henkel: Net Sales, 2023-2033 ($ Billion)

- Henkel: Revenue Share, By Segment, 2023 (%)

- Henkel: Revenue Share, By Region, 2023 (%)

- Indium: Net Sales, 2023-2033 ($ Billion)

- Indium: Revenue Share, By Segment, 2023 (%)

- Indium: Revenue Share, By Region, 2023 (%)

- Inventec: Net Sales, 2023-2033 ($ Billion)

- Inventec: Revenue Share, By Segment, 2023 (%)

- Inventec: Revenue Share, By Region, 2023 (%)

- KAWADA: Net Sales, 2023-2033 ($ Billion)

- KAWADA: Revenue Share, By Segment, 2023 (%)

- KAWADA: Revenue Share, By Region, 2023 (%)

- Kester(ITW): Net Sales, 2023-2033 ($ Billion)

- Kester(ITW): Revenue Share, By Segment, 2023 (%)

- Kester(ITW): Revenue Share, By Region, 2023 (%)

- KOKI: Net Sales, 2023-2033 ($ Billion)

- KOKI: Revenue Share, By Segment, 2023 (%)

- KOKI: Revenue Share, By Region, 2023 (%)

- MKE: Net Sales, 2023-2033 ($ Billion)

- MKE: Revenue Share, By Segment, 2023 (%)

- MKE: Revenue Share, By Region, 2023 (%)

- Nihon Superior: Net Sales, 2023-2033 ($ Billion)

- Nihon Superior: Revenue Share, By Segment, 2023 (%)

- Nihon Superior: Revenue Share, By Region, 2023 (%)

- Nippon Micrometal: Net Sales, 2023-2033 ($ Billion)

- Nippon Micrometal: Revenue Share, By Segment, 2023 (%)

- Nippon Micrometal: Revenue Share, By Region, 2023 (%)

- PMTC: Net Sales, 2023-2033 ($ Billion)

- PMTC: Revenue Share, By Segment, 2023 (%)

- PMTC: Revenue Share, By Region, 2023 (%)

- Senju Metal: Net Sales, 2023-2033 ($ Billion)

- Senju Metal: Revenue Share, By Segment, 2023 (%)

- Senju Metal: Revenue Share, By Region, 2023 (%)

- Shanghai hiking solder material: Net Sales, 2023-2033 ($ Billion)

- Shanghai hiking solder material: Revenue Share, By Segment, 2023 (%)

- Shanghai hiking solder material: Revenue Share, By Region, 2023 (%)

- Shenmao Technology: Net Sales, 2023-2033 ($ Billion)

- Shenmao Technology: Revenue Share, By Segment, 2023 (%)

- Shenmao Technology: Revenue Share, By Region, 2023 (%)

- Shenzhen Bright: Net Sales, 2023-2033 ($ Billion)

- Shenzhen Bright: Revenue Share, By Segment, 2023 (%)

- Shenzhen Bright: Revenue Share, By Region, 2023 (%)

- Tamura: Net Sales, 2023-2033 ($ Billion)

- Tamura: Revenue Share, By Segment, 2023 (%)

- Tamura: Revenue Share, By Region, 2023 (%)

- Tongfang Tech: Net Sales, 2023-2033 ($ Billion)

- Tongfang Tech: Revenue Share, By Segment, 2023 (%)

- Tongfang Tech: Revenue Share, By Region, 2023 (%)

- Yashida: Net Sales, 2023-2033 ($ Billion)

- Yashida: Revenue Share, By Segment, 2023 (%)

- Yashida: Revenue Share, By Region, 2023 (%)

- YCTC: Net Sales, 2023-2033 ($ Billion)

- YCTC: Revenue Share, By Segment, 2023 (%)

- YCTC: Revenue Share, By Region, 2023 (%)

- Yong An: Net Sales, 2023-2033 ($ Billion)

- Yong An: Revenue Share, By Segment, 2023 (%)

- Yong An: Revenue Share, By Region, 2023 (%)

Infinitive Data Research provides comprehensive market research, offering in-depth market analysis to help companies understand their target market and industry competition. This research predicts the market acceptance of your brand and products, ensuring informed decision-making for business success.

Competitor Analysis in the Electronics Interconnect Solder Materials Industry

Conducting a competitor analysis involves identifying competitors within the Electronics Interconnect Solder Materials industry and studying their various marketing strategies. This comparative data allows you to assess your company's strengths and weaknesses relative to competitors, providing insights to enhance your market position.

Importance of Continuous Market Research

Consistently conducting market research is essential for minimizing risk at every stage of business operations. Electronics Interconnect Solder Materials market research enables you to collect qualitative and quantitative data, which, when properly analyzed, leads to wise decisions that align with user and customer needs. Below are some crucial lessons learned through the Electronics Interconnect Solder Materials market research process:

Key Dimensions of Electronics Interconnect Solder Materials Market Analysis

- Trend and Pattern Identification: Analyzing data to spot market trends and patterns.

- Pricing Analysis: Assessing keyword pricing strategies.

- Actionable Insights: Implementing insights derived from data analysis.

- Market Potential: Evaluating the potential of the Electronics Interconnect Solder Materials market.

- Competitor Analysis: Studying competitors' strategies and performance.

- Location Analysis: Assessing optimal locations for market penetration.

- Distribution Channels Analysis: Evaluating the effectiveness of distribution channels.

- Market Size and Growth Rate: Measuring market size and growth potential.

- Market Profitability: Assessing profitability prospects.

- Key Success Factors: Identifying critical factors for success.

- Cost Structure: Understanding the cost structure within the Electronics Interconnect Solder Materials industry.

Target Audience for the Report

This report is valuable for a diverse audience, including:

- Electronics Interconnect Solder Materials Market Manufacturers: To understand market dynamics and enhance production strategies.

- Investors and Financing Companies: To assess investment opportunities and risks.

- Electronics Interconnect Solder Materials Market Suppliers: To identify market demands and supply chain efficiencies.

Necessity of the Report

Making Crucial Business Decisions

Understanding the Electronics Interconnect Solder Materials market, competition, and industry landscape is vital for making informed business decisions. Without current and relevant market research, decisions may be based on outdated or irrelevant information, potentially harming the business.

Securing Investment Funds

Attracting investors requires demonstrating thorough market research. Investors need assurance that you understand the sector, current and potential competition, and whether your idea addresses a market need.

Identifying New Business Opportunities

Electronics Interconnect Solder Materials market research goes beyond understanding trends and consumer behavior. It identifies new revenue streams and opportunities for business pivots. These insights can lead to strategic changes in the business model, promoting growth and adapting to market challenges.

Avoiding Business Failures

Market research also plays a crucial role in risk mitigation. It can reveal when not to pursue certain actions, saving the company from potential losses in revenue, brand image, and more. This proactive approach is often overlooked but is essential for long-term success.

Conclusion

Infinitive Data Research's comprehensive Electronics Interconnect Solder Materials market research provides critical insights for making solid business decisions, securing investments, identifying new opportunities, and avoiding potential failures. Understanding market dynamics through continuous research ensures your company remains competitive and thrives in the Electronics Interconnect Solder Materials industry.