Chemical Industry Vacuum Pump Market Growth CAGR Overview

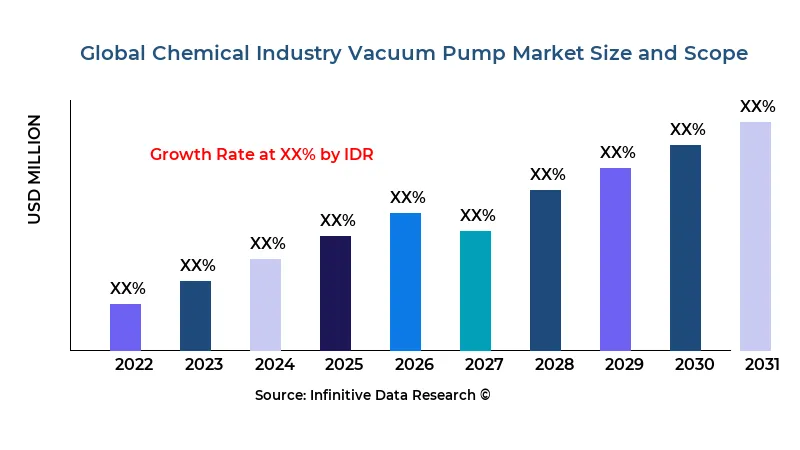

According to research by Infinitive Data Research, the global Chemical Industry Vacuum Pump Market size was valued at USD 2.8 Bln (billion) in 2024 and is Calculated to reach USD 3.4 Bln (billion) by the end of 2032, growing at an anticipated compound annual growth rate (CAGR) of 7.8% during the forecast period 2024 to 2032. This projected growth is driven by its increasing adoption across Machinery & Equipment industries such as Petrochemical Industry, Chemical Industry, Pharmaceutical industry, OthersThe chemical industry vacuum pump market is defined by rapid technological evolution and a strong demand for high-performance equipment in chemical processing. Manufacturers are increasingly adopting advanced vacuum pump solutions that cater to a diverse range of chemical applications, from process engineering to environmental control systems. The market is characterized by the integration of computer-aided design and automation in pump operations, leading to improved reliability and energy efficiency. This innovation has allowed companies to meet stringent industry standards and regulatory requirements while maintaining profitability.

Industry players are operating in a highly competitive environment where innovation is vital for survival. This sector has experienced steady growth due to increased investments in research and development. Rising environmental concerns and the need for cleaner production processes have spurred the deployment of vacuum pump systems that ensure safe and effective chemical processing. Manufacturers continuously innovate to deliver products that reduce operational downtime and support continuous production cycles, thereby fostering long-term customer loyalty and market expansion.

A robust supply chain and global standardization have been key to the chemical industry vacuum pump market. Companies have worked collaboratively with suppliers and service providers to ensure that maintenance and repair cycles do not disrupt production schedules. This synergy between industry partners has resulted in the development of reliable and cost-effective solutions that cater to large-scale chemical manufacturing plants. Companies in this space are known for their long-term contracts with major chemical producers, which provide stable revenue streams and encourage further investment in technology.

The market is witnessing consolidation as well as strategic alliances that seek to integrate diverse technological competencies under one roof. Mergers and partnerships are enabling companies to pool resources, streamline operations, and launch next-generation vacuum pump solutions. Such collaborations are fostering innovation and ensuring that companies remain competitive in an environment where regulatory compliances and operational efficiency are of paramount importance. These market dynamics underscore the importance of strategic agility and investment in advanced technologies within the chemical industry vacuum pump market.

>>> Understand The Key Trends Shaping This Market:- Download PDF Sample

Chemical Industry Vacuum Pump Market Growth Factors

The primary factors contributing to the growth of the chemical industry vacuum pump market include rising demand for energy-efficient and reliable systems. Increasing adoption of automation and smart technology in chemical processes has driven the need for more precise and efficient vacuum pump operations. The industry's focus on reducing maintenance downtime and optimizing energy usage has led to significant investments in modern pump designs. These investments have a direct impact on operational costs and overall system performance, bolstering industry growth.

Another growth driver is the pressure to adhere to environmental regulations and safety standards. Stricter emissions standards and enhanced safety protocols require the integration of advanced vacuum pump systems that minimize environmental hazards and ensure worker safety. This regulatory pressure has motivated companies to upgrade existing systems and invest in next-generation technologies that align with modern environmental policies. The resultant improvements in process efficiency and safety have been a decisive factor in expanding the market, as chemical manufacturers seek compliant and sustainable solutions.

Technological innovations also play a critical role in market expansion. Ongoing research and development have led to the creation of highly efficient and durable vacuum pumps. These systems offer benefits such as reduced energy consumption, extended operational life, and improved reliability. Innovative designs that incorporate digital controls and remote monitoring capabilities are further driving market penetration, especially among large-scale chemical production facilities. The continuous improvements in technical capabilities ensure that vacuum pump systems remain a key component in the advancement of chemical processing technology.

Global economic growth, particularly in emerging markets, presents new opportunities for the chemical industry vacuum pump segment. Rapid industrialization combined with expanding chemical manufacturing sectors in these regions drives demand for advanced production systems. Investments in infrastructure and technology by both private and public sectors are creating a favorable environment for the deployment of modern vacuum pump systems. These initiatives are expected to stimulate market growth further, as manufacturers seek to capitalize on the operational efficiency and safety benefits provided by innovative vacuum pump solutions.

Market Analysis By Competitors

- Bgs General Srl

- Flowserve SIHI Pumps

- RHEINH�TTE Pumpen GmbH

- Zibo Vacuum Equipment Plant Co.,Ltd

- PPI Pumps

- Gardner Denver

- Pfeiffer Vacuum

- ULVAC

- Atlas Copco

- Tuthill

- Graham

- Dekker

- Becker

- Busch Vacuum

- KNF Neuberger

- Tsurumi Manufacturing

- Ebara

- Sterling SIHI

- Samson Pump

- Value Specializes

- Wenling Tingwei

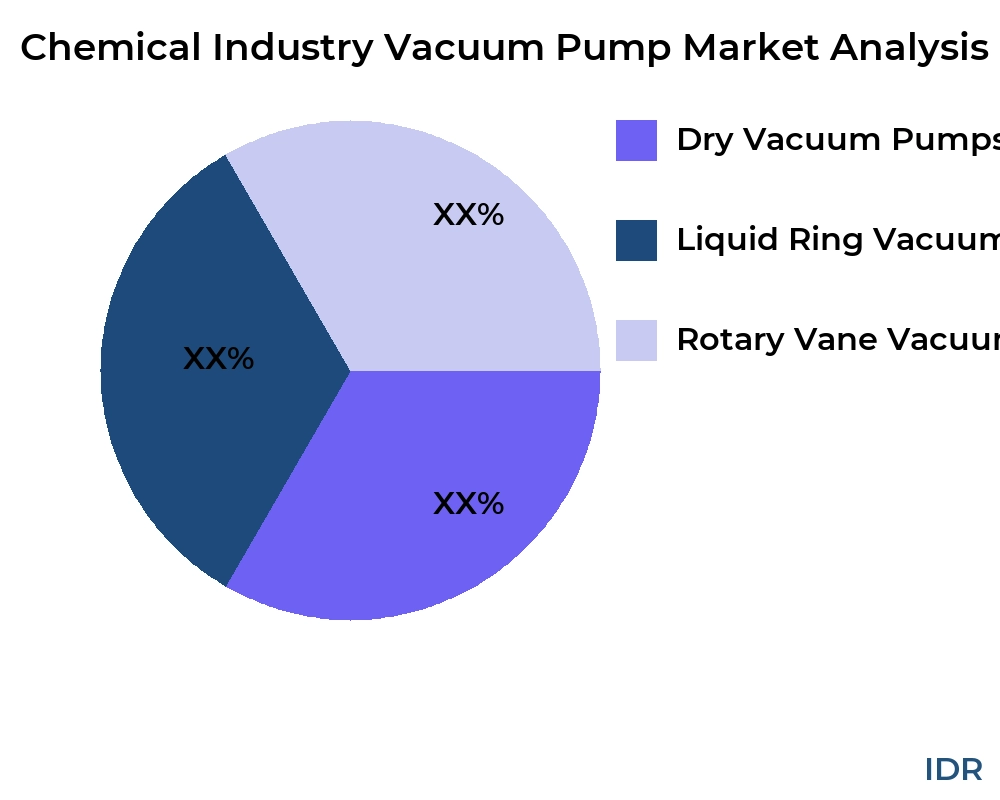

By Product Type

- Dry Vacuum Pumps

- Liquid Ring VacuumPump

- Rotary Vane Vacuum Pump

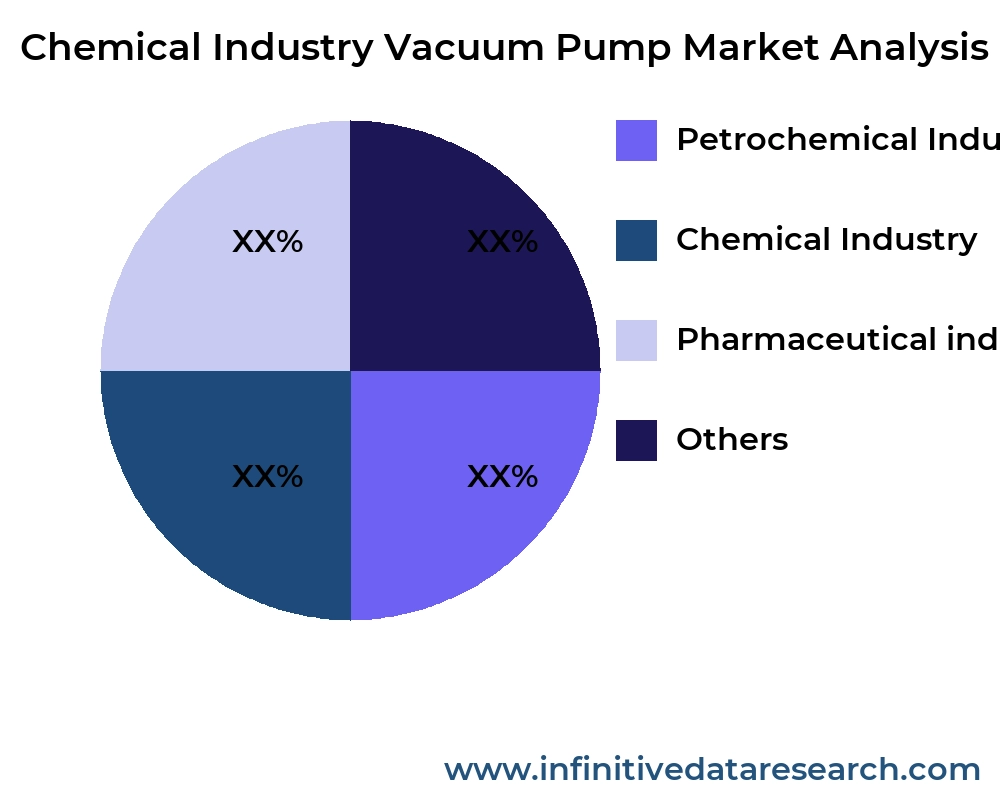

By Application

- Petrochemical Industry

- Chemical Industry

- Pharmaceutical industry

- Others

>>> Understand The Key Trends Shaping This Market:- Understand The Key Trends Shaping This Market:-

Chemical Industry Vacuum Pump Market Segment Analysis

Distribution ChannelThe distribution channels for chemical industry vacuum pumps are highly diversified, spanning direct sales, specialized distributors, and online channels. Established players have developed robust networks to ensure prompt delivery of technical support and replacement parts, enhancing the reliability of service. This strategic distribution approach not only improves customer satisfaction but also enables manufacturers to maintain a competitive edge in an increasingly globalized market. The emphasis is on offering integrated solutions that combine product sales with tailored service contracts, ensuring that end-users receive comprehensive support across the product lifecycle.

CompatibilityIn this segment, compatibility refers to the ability of vacuum pumps to integrate smoothly with existing chemical process infrastructure. Manufacturers design their products to be adaptable to a wide range of operating conditions, ensuring seamless integration with automation systems and process controls. The emphasis on compatibility extends to compliance with international standards and compatibility with ancillary equipment, thereby minimizing installation challenges. Companies invest in extensive testing and validation procedures to ensure that their vacuum pump systems can operate effectively alongside other process components, ensuring optimal performance even under demanding industrial conditions.

PricePrice segmentation in the chemical industry vacuum pump market is complex due to the range of product variants and performance specifications. Premium systems that incorporate advanced monitoring and control features are typically priced higher, targeting large-scale industrial users who prioritize reliability and efficiency. Meanwhile, more basic models cater to smaller or mid-sized operations that are focused on cost-effectiveness. Manufacturers often adopt a value-based pricing strategy that aligns product features with customer needs, balancing capital expenditure with long-term operational savings. As such, pricing decisions reflect both the technological sophistication and the overall value proposition offered by each system.

Product TypeProduct type segmentation in this market is driven by the diverse applications of vacuum pumps across chemical processes. Variants include rotary vane, liquid ring, and dry screw vacuum pumps, each tailored to different operational requirements. Manufacturers distinguish product types based on factors such as energy efficiency, maintenance requirements, and operating environment compatibility. This segmentation allows producers to address the specific needs of various industrial sectors, whether in heavy chemical processing or specialized laboratory environments. Continuous product innovation and diversification are critical to meeting the evolving demands of end-user applications, ensuring that each product type remains competitive on multiple fronts.

| REPORT ATTRIBUTES | DETAILS |

|---|---|

| Study Period |

2019-2032 |

| Base Year |

2023 |

| Forecast Period |

2024-2032 |

| Historical Period |

2019-2022 |

| Unit |

Value (USD Billion) |

| Key Companies Profiled |

Bgs General Srl, Flowserve SIHI Pumps, RHEINH�TTE Pumpen GmbH, Zibo Vacuum Equipment Plant Co.,Ltd, PPI Pumps, Gardner Denver, Pfeiffer Vacuum, ULVAC, Atlas Copco, Tuthill, Graham, Dekker, Becker, Busch Vacuum, KNF Neuberger, Tsurumi Manufacturing, Ebara, Sterling SIHI, Samson Pump, Value Specializes, Wenling Tingwei |

| Segments Covered |

By Product |

| Customization Scope |

Free report customization (equivalent to up to 3 analyst working days) with purchase. Addition or alteration to country, regional and segment scope |

>>> Overview of Market Analysis:- Download PDF Sample

Chemical Industry Vacuum Pump Market Regional Analysis

In North America, the chemical industry vacuum pump market benefits from a mature industrial base with significant investments in infrastructure and technology. The region’s focus on improving process efficiency and operational safety has driven the adoption of advanced vacuum pump systems. There is a consistent emphasis on retrofitting existing facilities with state-of-the-art technology, which has led to sustained growth in this segment. The North American market is characterized by well-established service networks and a high level of technical expertise, ensuring that manufacturers can deliver and maintain cutting-edge solutions effectively.

Europe is witnessing robust demand for chemical processing equipment amid strict environmental and safety regulations. The region’s commitment to reducing carbon emissions and enhancing production efficiency has led to increased investments in vacuum pump technology. European manufacturers benefit from advanced research institutions that collaborate with industry to develop innovative solutions. The regulatory environment acts as a catalyst for modernization in the chemical industry, with companies rapidly adopting new technologies to stay ahead of evolving standards. As a result, Europe remains a key market for high-end vacuum pump systems that emphasize both performance and environmental compliance.

The Asia-Pacific region is emerging as a dynamic hub for the chemical industry vacuum pump market due to rapid industrial growth and expanding manufacturing activities. Countries within this region are investing heavily in modern production processes, which in turn drive the demand for efficient vacuum systems. The market is marked by a diverse range of players, from established multinational corporations to agile local innovators. Increasing investments in infrastructure and a growing focus on energy efficiency are expected to create a fertile environment for the further adoption of advanced vacuum pump solutions throughout the region.

In South America, growth in the chemical industry vacuum pump market is fueled by industrial modernization and increasing foreign investments. The region is gradually transitioning from traditional technologies to state-of-the-art production systems that offer improved energy efficiency and lower operational costs. Government initiatives aimed at boosting industrial competitiveness and technological adoption have further supported market growth. South American manufacturers are increasingly partnering with global technology providers to upgrade their systems, ensuring that vacuum pump solutions are efficient and reliable. This continued focus on modernization is expected to drive long-term growth, positioning South America as a promising market for advanced chemical processing equipment.

global Chemical Industry Vacuum Pump market revenue (usd million) comparison by players 2024-2032

| Company/players | 2021 | 2022 | 2023 | 2024 | ... | (2032) |

|---|---|---|---|---|---|---|

| Bgs General Srl | XX | XX | XX | XX | XX | XX |

| Flowserve SIHI Pumps | XX | XX | XX | XX | XX | XX |

| RHEINH�TTE Pumpen GmbH | XX | XX | XX | XX | XX | XX |

| Zibo Vacuum Equipment Plant Co.,Ltd | XX | XX | XX | XX | XX | XX |

| PPI Pumps | XX | XX | XX | XX | XX | XX |

| Gardner Denver | XX | XX | XX | XX | XX | XX |

| Pfeiffer Vacuum | XX | XX | XX | XX | XX | XX |

| ULVAC | XX | XX | XX | XX | XX | XX |

| Atlas Copco | XX | XX | XX | XX | XX | XX |

| Tuthill | XX | XX | XX | XX | XX | XX |

| Graham | XX | XX | XX | XX | XX | XX |

| Dekker | XX | XX | XX | XX | XX | XX |

| Becker | XX | XX | XX | XX | XX | XX |

| Busch Vacuum | XX | XX | XX | XX | XX | XX |

| KNF Neuberger | XX | XX | XX | XX | XX | XX |

| Tsurumi Manufacturing | XX | XX | XX | XX | XX | XX |

| Ebara | XX | XX | XX | XX | XX | XX |

| Sterling SIHI | XX | XX | XX | XX | XX | XX |

| Samson Pump | XX | XX | XX | XX | XX | XX |

| Value Specializes | XX | XX | XX | XX | XX | XX |

| Wenling Tingwei | XX | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX | XX |

global Chemical Industry Vacuum Pump market revenue (usd million) comparison by product type 2024-2032

Product Type

2023

2024

...

2032

CAGR%(2024-32)

Dry Vacuum Pumps

XX

XX

XX

XX

XX

Liquid Ring VacuumPump

XX

XX

XX

XX

XX

Rotary Vane Vacuum Pump

XX

XX

XX

XX

XX

Total

XX

XX

XX

XX

XX

| Product Type | 2023 | 2024 | ... | 2032 | CAGR%(2024-32) |

|---|---|---|---|---|---|

| Dry Vacuum Pumps | XX | XX | XX | XX | XX |

| Liquid Ring VacuumPump | XX | XX | XX | XX | XX |

| Rotary Vane Vacuum Pump | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX |

global Chemical Industry Vacuum Pump market revenue (usd million) comparison by application 2024-2032

Application

2023

2024

...

2032

CAGR%(2024-32)

Petrochemical Industry

XX

XX

XX

XX

XX

Chemical Industry

XX

XX

XX

XX

XX

Pharmaceutical industry

XX

XX

XX

XX

XX

Others

XX

XX

XX

XX

XX

Total

XX

XX

XX

XX

XX

| Application | 2023 | 2024 | ... | 2032 | CAGR%(2024-32) |

|---|---|---|---|---|---|

| Petrochemical Industry | XX | XX | XX | XX | XX |

| Chemical Industry | XX | XX | XX | XX | XX |

| Pharmaceutical industry | XX | XX | XX | XX | XX |

| Others | XX | XX | XX | XX | XX |

| Total | XX | XX | XX | XX | XX |

>>> Market Understand Through Graph And Chart:- Download PDF Sample

Chemical Industry Vacuum Pump Market Competitive Insights

The competitive landscape in the chemical industry vacuum pump market is characterized by high innovation and strategic investments in R&D. Industry leaders continuously update their product lines to meet the latest technological standards, thereby reinforcing their market positions. Companies are engaging in partnerships and acquisitions to enhance their product portfolios and increase operational efficiency. These strategic moves have intensified competition, forcing all players to focus on speed-to-market and comprehensive service offerings that cater to the specific needs of chemical manufacturers.

Market players are also differentiating themselves through customized solutions and after-sales support, which have become critical factors in customer retention. In a market where downtime can be extremely costly, rapid service response and effective maintenance solutions add substantial value to the core product. Enhanced service networks and technical expertise are often the distinguishing factors that set industry leaders apart from their competitors. This focus on total lifecycle solutions has not only improved customer satisfaction but has also created stable revenue streams through long-term service contracts and maintenance agreements.

Technological innovation and adaptability remain at the forefront of competitive strategy. Firms are increasingly investing in digitalization, integrating sensors and remote monitoring capabilities to optimize system performance and predict maintenance needs. These advancements have led to a new generation of vacuum pump systems that provide real-time process insights and improved operational control. Such proactive measures have positioned key players as trusted partners capable of driving operational improvements for chemical manufacturers. The proactive approach to digital innovation and process optimization is central to maintaining a competitive advantage in this fast-evolving market.

The market has also seen a trend toward consolidation, as larger companies acquire niche players to broaden their technological expertise and geographical presence. This consolidation allows the integrated companies to benefit from improved economies of scale, more robust supply chains, and expanded customer bases. In addition, the drive to offer comprehensive and globally competitive solutions has resulted in strategic alliances that provide synergies in both research and market deployment. The evolving competitive landscape is thus defined by the interplay between innovative technologies and strategic business practices, ensuring that only the most agile and adaptive companies survive in the long term.

Chemical Industry Vacuum Pump Market Competitors

United States

-

VacuumTech Industries

-

ChemEquip Solutions

-

AeroPump Systems

-

FlowMaster Corp.

-

ProcessPro Technologies

Germany

-

VakuumTech GmbH

-

ChemPump Innovations

-

EuroVac Systems

-

ProcessFlow AG

-

Innovatech Pumps

China

-

SinoVacuum Co.

-

ChemProcess Equipment

-

DragonPump Industries

-

TechVac Solutions

-

AdvanceChem Systems

India

-

IndusVac Pump Works

-

ChemFlow Industries

-

Bharat Process Systems

-

Innovate Pump Technologies

-

ProcessVantage Ltd.

Brazil

-

BrasilVac Equipamentos

-

ChemTech Brasil

-

ProcessFlow Sistemas

-

InovaPump Brasil

-

VitalVac Industries

France

-

VacuTech France

-

ChemEquip Industries

-

EuroProcess Systems

-

FlowInnov France

-

TechPump Solutions

Chemical Industry Vacuum Pump Market Top competitors

Alpha ChemPumps Inc.

Alpha ChemPumps Inc. is recognized as a dominant force in the chemical industry vacuum pump sector, providing highly efficient and innovative pump solutions to large-scale chemical plants. Their technologically advanced designs have set industry benchmarks, and their commitment to rigorous quality control has earned them a loyal customer base. The company continuously invests in research and development to pioneer new techniques that reduce energy consumption and operational downtime. With a wide global network of service centers, Alpha ChemPumps ensures rapid maintenance and a high level of customer satisfaction. Their strong market presence is underpinned by long-term contracts with major chemical manufacturers. The company’s reputation for reliability and efficiency has solidified its status as one of the market’s leading competitors.

Beta Process Systems

Beta Process Systems stands out for its innovative approach to developing chemical process equipment, particularly high-performance vacuum pump systems. The firm is known for its dedication to integrating digital controls and remote monitoring features into its products, helping customers achieve optimal process efficiency. Beta Process Systems has successfully expanded its market presence by leveraging state-of-the-art manufacturing facilities and a skilled engineering team. Their products are widely acclaimed for providing energy savings and maintenance ease. The company has built strong relationships with key industry players, ensuring steady revenue growth and technological advancement. Beta Process Systems’ proactive strategy has earned it a position of prominence in the competitive landscape.

Gamma Vacuum Technologies

Gamma Vacuum Technologies has established a formidable reputation in the chemical industry through its innovative and reliable vacuum pump solutions. The company’s products are engineered to meet the most demanding operational requirements, ensuring continuous and efficient chemical processing. A dedicated research team focuses on reducing emissions and optimizing performance, which has led to several breakthrough technologies. Gamma Vacuum Technologies continuously expands its product portfolio to cater to both standard and specialized applications. Their global distribution network ensures that products and services are available even in the most challenging markets. This commitment to quality and technological innovation places Gamma Vacuum Technologies among the top competitors in the industry.

Delta Flow Solutions

Delta Flow Solutions is a reputable name in the market, known for providing robust vacuum pump systems that cater specifically to the chemical processing industry. The company emphasizes energy efficiency, durability, and ease of maintenance as its core product attributes. Delta Flow Solutions has invested considerably in state-of-the-art production facilities and quality assurance processes to uphold high standards. Their customer-centric approach focuses on long-term service relationships and customized product solutions to meet unique industrial challenges. The company’s global outreach and technical expertise contribute to its strong market presence. This leadership position is reinforced by continuous innovation and consistent performance improvements across its product lines.

Epsilon Industrial Pumps

Epsilon Industrial Pumps has carved out a significant market share through its emphasis on developing high-efficiency, low-maintenance vacuum pump systems for the chemical industry. Their comprehensive product range is engineered to ensure optimal performance under variable operating conditions. Epsilon Industrial Pumps maintains rigorous quality control and a responsive service network, making them a preferred partner for many high-value industrial projects. They are committed to sustainability and reducing the ecological footprint of chemical processing. The company’s investments in advanced manufacturing techniques and digital technology further reinforce its leadership in the market. Epsilon Industrial Pumps is widely recognized for its reliable and innovative product solutions in the sector.

Zeta Vacuum Solutions

Zeta Vacuum Solutions has emerged as one of the most competitive entities in the vacuum pump market through its focus on reliability, durability, and technological integration. Their products are distinguished by their ability to enhance process efficiency while reducing energy consumption. Zeta Vacuum Solutions leverages advanced digital monitoring systems, which help in predictive maintenance and reduce operational interruptions. They have established strong partnerships with chemical manufacturers across the globe, ensuring a broad and stable customer base. With continuous improvements in design and performance, Zeta Vacuum Solutions continues to be a favored choice in markets that demand high-end process solutions. Their commitment to innovation and customer support positions them at the forefront of the competitive landscape.

Eta Process Technologies

Eta Process Technologies is celebrated in the chemical vacuum pump market for its innovative design and adaptive technology solutions. The company provides advanced systems that are tailored to meet the specific needs of large-scale chemical operations. Its product offerings are marked by significant improvements in energy efficiency and operational reliability. Eta Process Technologies boasts a strong R&D team that is dedicated to expanding their product applications and overcoming technical limitations. Their global service network ensures prompt after-sales support and maintenance, which is critical in reducing downtime. Overall, Eta Process Technologies has earned a reputation for quality and innovation, making it a prominent competitor in the sector.

Theta ChemEquip Solutions

Theta ChemEquip Solutions has consistently demonstrated a commitment to developing high-performance vacuum pump systems for the chemical industry. The company places great emphasis on innovation, as it continuously updates its technologies to improve operational efficiency. Their products have gained widespread acclaim for their precision engineering and robust performance under intensive industrial use. Theta ChemEquip Solutions also invests in customer training programs to ensure optimal product utilization and minimize downtime. Their extensive global distribution network further reinforces their market position. This blend of innovation, customer support, and technical expertise has solidified Theta ChemEquip Solutions’ standing as a key player in the competitive market.

Iota Vacuum Systems

Iota Vacuum Systems is acknowledged as a leading figure in the chemical industry vacuum pump segment, with a reputation for pioneering products that offer both efficiency and reliability. Their vacuum systems are developed using advanced technologies that emphasize sustainability and low energy consumption. Iota Vacuum Systems has invested in comprehensive quality and testing programs to ensure that each product meets industry standards. The company’s commitment to continuous improvement and customer service has helped foster long-term partnerships with key chemical processing companies. Their strategic focus on innovation and operational excellence reinforces their competitive position. Iota Vacuum Systems remains an influential contributor to advancements in the vacuum pump market.

Kappa Industrial Engineering

Kappa Industrial Engineering has established itself as a comprehensive provider of vacuum pump solutions for the chemical sector. Its broad portfolio of products is designed to cater to a variety of industrial processes with a focus on efficiency and durability. The company’s technologically advanced production facilities and dedicated engineering team have enabled it to deliver products that meet stringent industrial requirements. Kappa Industrial Engineering is also known for its proactive customer service initiatives that ensure sustained operational performance. Their strategic investments in new technology and process automation continuously push the envelope in the field. This commitment to excellence and innovation makes Kappa Industrial Engineering a significant competitor in the rapidly evolving market.

The report provides a detailed analysis of the Chemical Industry Vacuum Pump market across various regions, highlighting the unique market dynamics and growth opportunities in each region.

- US

- Canada

- Mexico

- UK

- Germany

- France

- Italy

- Russia

- Spain

- Switzerland

- Austria

- Belgium

- Rest of Europe

- China

- Japan

- South Korea

- Indonesia

- Vietnam

- Philippines

- Australia

- Thailand

- Singapore

- Rest of APAC

- UAE

- Saudi Arabia

- Egypt

- South Africa

- Israel

- Rest of MEA

- Brazil

- Argentina

- Rest of Latin America

>>> Need A Different Region Or Segment? Download PDF Sample

Key Takeaways

- The global Chemical Industry Vacuum Pump market is expected to grow significantly from 2024 to 2032, driven by technological advancements, increasing demand, and government investments in urbanization.

- The market is characterized by a diverse range of manufacturers, product types, and applications, catering to different consumer needs and preferences.

- Regional insights highlight the unique market dynamics and growth opportunities in various regions, including North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

- The competitive landscape features key players who have created a dynamic and diverse market environment through collaborations, mergers and acquisitions, and innovative product developments.

- Market trends such as technological advancements, sustainability, customization, and digital transformation are shaping the growth and development of the Chemical Industry Vacuum Pump market.

- Despite the positive outlook, the market faces challenges such as regulatory compliance, high initial investment costs, and economic uncertainties.

- The report provides comprehensive coverage of market size, market share, growth factors, and strategic insights to help businesses navigate the dynamic Chemical Industry Vacuum Pump market and achieve long-term success.

By leveraging the information provided in this report, businesses can develop effective strategies, address market challenges, and capitalize on growth opportunities to ensure sustainable growth and long-term success in the global Chemical Industry Vacuum Pump market.

- Introduction

- Objectives of the Study

- Market Definition

- Research Scope

- Currency

- Key Target Audience

- Research Methodology and Assumptions

- Executive Summary

- Premium Insights

- Porter’s Five Forces Analysis

- Value Chain Analysis

- Top Investment Pockets

- Industry Trends

- Market Dynamics

- Market Evaluation

- Drivers

- Restraints

- Opportunities

- Challenges

- Global Chemical Industry Vacuum Pump Market Analysis and Projection, By Companies

- Segment Overview

- Bgs General Srl

- Flowserve SIHI Pumps

- RHEINH�TTE Pumpen GmbH

- Zibo Vacuum Equipment Plant Co.,Ltd

- PPI Pumps

- Gardner Denver

- Pfeiffer Vacuum

- ULVAC

- Atlas Copco

- Tuthill

- Graham

- Dekker

- Becker

- Busch Vacuum

- KNF Neuberger

- Tsurumi Manufacturing

- Ebara

- Sterling SIHI

- Samson Pump

- Value Specializes

- Wenling Tingwei

- Global Chemical Industry Vacuum Pump Market Analysis and Projection, By Type

- Segment Overview

- Dry Vacuum Pumps

- Liquid Ring VacuumPump

- Rotary Vane Vacuum Pump

- Global Chemical Industry Vacuum Pump Market Analysis and Projection, By Application

- Segment Overview

- Petrochemical Industry

- Chemical Industry

- Pharmaceutical industry

- Others

- Global Chemical Industry Vacuum Pump Market Analysis and Projection, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Russia

- Spain

- Switzerland

- Austria

- Belgium

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- Indonesia

- Vietnam

- Philippines

- Australia

- Thailand

- Singapore

- Rest of APAC

- Middle East

- UAE

- Saudi Arabia

- Egypt

- South Africa

- Israel

- Rest of MEA

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Global Chemical Industry Vacuum Pump Market-Competitive Landscape

- Overview

- Market Share of Key Players in the Chemical Industry Vacuum Pump Market

- Global Company Market Share

- North America Company Market Share

- Europe Company Market Share

- APAC Company Market Share

- Competitive Situations and Trends

- Coverage Launches and Developments

- Partnerships, Collaborations, and Agreements

- Mergers & Acquisitions

- Expansions

- Company Profiles

- Bgs General Srl

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Flowserve SIHI Pumps

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- RHEINH�TTE Pumpen GmbH

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Zibo Vacuum Equipment Plant Co.,Ltd

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- PPI Pumps

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Gardner Denver

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Pfeiffer Vacuum

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- ULVAC

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Atlas Copco

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Tuthill

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Graham

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Dekker

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Becker

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Busch Vacuum

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- KNF Neuberger

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Tsurumi Manufacturing

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Ebara

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Sterling SIHI

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Samson Pump

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Value Specializes

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

- Wenling Tingwei

- Business Overview

- Company Snapshot

- Company Market Share Analysis

- Company Coverage Portfolio

- Recent Developments

- SWOT Analysis

List of Table

- Drivers of Global Chemical Industry Vacuum Pump Market: Impact Analysis

- Restraints of Global Chemical Industry Vacuum Pump Market: Impact Analysis

- Global Chemical Industry Vacuum Pump Market, By Technology, 2023-2032(USD Billion)

- global Dry Vacuum Pumps, Chemical Industry Vacuum Pump Market, By Region, 2023-2032(USD Billion)

- global Liquid Ring VacuumPump, Chemical Industry Vacuum Pump Market, By Region, 2023-2032(USD Billion)

- global Rotary Vane Vacuum Pump, Chemical Industry Vacuum Pump Market, By Region, 2023-2032(USD Billion)

- global Petrochemical Industry, Chemical Industry Vacuum Pump Market, By Region, 2023-2032(USD Billion)

- global Chemical Industry, Chemical Industry Vacuum Pump Market, By Region, 2023-2032(USD Billion)

- global Pharmaceutical industry, Chemical Industry Vacuum Pump Market, By Region, 2023-2032(USD Billion)

- global Others, Chemical Industry Vacuum Pump Market, By Region, 2023-2032(USD Billion)

List of Figures

- Global Chemical Industry Vacuum Pump Market Segmentation

- Chemical Industry Vacuum Pump Market: Research Methodology

- Market Size Estimation Methodology: Bottom-Up Approach

- Market Size Estimation Methodology: Top-down Approach

- Data Triangulation

- Porter’s Five Forces Analysis

- Value Chain Analysis

- Top investment pocket in the Chemical Industry Vacuum Pump Market

- Top Winning Strategies, 2023-2032

- Top Winning Strategies, By Development, 2023-2032(%)

- Top Winning Strategies, By Company, 2023-2032

- Moderate Bargaining power of Buyers

- Moderate Bargaining power of Suppliers

- Moderate Bargaining power of New Entrants

- Low threat of Substitution

- High Competitive Rivalry

- Restraint and Drivers: Chemical Industry Vacuum Pump Market

- Chemical Industry Vacuum Pump Market Segmentation, By Technology

- Chemical Industry Vacuum Pump Market For Live Attenuated, By Region, 2023-2033 ($ Billion)

- Global Chemical Industry Vacuum Pump Market, By Technology, 2023-2032(USD Billion)

- global Dry Vacuum Pumps, Chemical Industry Vacuum Pump Market, By Region, 2023-2032(USD Billion)

- global Liquid Ring VacuumPump, Chemical Industry Vacuum Pump Market, By Region, 2023-2032(USD Billion)

- global Rotary Vane Vacuum Pump, Chemical Industry Vacuum Pump Market, By Region, 2023-2032(USD Billion)

- global Petrochemical Industry, Chemical Industry Vacuum Pump Market, By Region, 2023-2032(USD Billion)

- global Chemical Industry, Chemical Industry Vacuum Pump Market, By Region, 2023-2032(USD Billion)

- global Pharmaceutical industry, Chemical Industry Vacuum Pump Market, By Region, 2023-2032(USD Billion)

- global Others, Chemical Industry Vacuum Pump Market, By Region, 2023-2032(USD Billion)

- Bgs General Srl: Net Sales, 2023-2033 ($ Billion)

- Bgs General Srl: Revenue Share, By Segment, 2023 (%)

- Bgs General Srl: Revenue Share, By Region, 2023 (%)

- Flowserve SIHI Pumps: Net Sales, 2023-2033 ($ Billion)

- Flowserve SIHI Pumps: Revenue Share, By Segment, 2023 (%)

- Flowserve SIHI Pumps: Revenue Share, By Region, 2023 (%)

- RHEINH�TTE Pumpen GmbH: Net Sales, 2023-2033 ($ Billion)

- RHEINH�TTE Pumpen GmbH: Revenue Share, By Segment, 2023 (%)

- RHEINH�TTE Pumpen GmbH: Revenue Share, By Region, 2023 (%)

- Zibo Vacuum Equipment Plant Co.,Ltd: Net Sales, 2023-2033 ($ Billion)

- Zibo Vacuum Equipment Plant Co.,Ltd: Revenue Share, By Segment, 2023 (%)

- Zibo Vacuum Equipment Plant Co.,Ltd: Revenue Share, By Region, 2023 (%)

- PPI Pumps: Net Sales, 2023-2033 ($ Billion)

- PPI Pumps: Revenue Share, By Segment, 2023 (%)

- PPI Pumps: Revenue Share, By Region, 2023 (%)

- Gardner Denver: Net Sales, 2023-2033 ($ Billion)

- Gardner Denver: Revenue Share, By Segment, 2023 (%)

- Gardner Denver: Revenue Share, By Region, 2023 (%)

- Pfeiffer Vacuum: Net Sales, 2023-2033 ($ Billion)

- Pfeiffer Vacuum: Revenue Share, By Segment, 2023 (%)

- Pfeiffer Vacuum: Revenue Share, By Region, 2023 (%)

- ULVAC: Net Sales, 2023-2033 ($ Billion)

- ULVAC: Revenue Share, By Segment, 2023 (%)

- ULVAC: Revenue Share, By Region, 2023 (%)

- Atlas Copco: Net Sales, 2023-2033 ($ Billion)

- Atlas Copco: Revenue Share, By Segment, 2023 (%)

- Atlas Copco: Revenue Share, By Region, 2023 (%)

- Tuthill: Net Sales, 2023-2033 ($ Billion)

- Tuthill: Revenue Share, By Segment, 2023 (%)

- Tuthill: Revenue Share, By Region, 2023 (%)

- Graham: Net Sales, 2023-2033 ($ Billion)

- Graham: Revenue Share, By Segment, 2023 (%)

- Graham: Revenue Share, By Region, 2023 (%)

- Dekker: Net Sales, 2023-2033 ($ Billion)

- Dekker: Revenue Share, By Segment, 2023 (%)

- Dekker: Revenue Share, By Region, 2023 (%)

- Becker: Net Sales, 2023-2033 ($ Billion)

- Becker: Revenue Share, By Segment, 2023 (%)

- Becker: Revenue Share, By Region, 2023 (%)

- Busch Vacuum: Net Sales, 2023-2033 ($ Billion)

- Busch Vacuum: Revenue Share, By Segment, 2023 (%)

- Busch Vacuum: Revenue Share, By Region, 2023 (%)

- KNF Neuberger: Net Sales, 2023-2033 ($ Billion)

- KNF Neuberger: Revenue Share, By Segment, 2023 (%)

- KNF Neuberger: Revenue Share, By Region, 2023 (%)

- Tsurumi Manufacturing: Net Sales, 2023-2033 ($ Billion)

- Tsurumi Manufacturing: Revenue Share, By Segment, 2023 (%)

- Tsurumi Manufacturing: Revenue Share, By Region, 2023 (%)

- Ebara: Net Sales, 2023-2033 ($ Billion)

- Ebara: Revenue Share, By Segment, 2023 (%)

- Ebara: Revenue Share, By Region, 2023 (%)

- Sterling SIHI: Net Sales, 2023-2033 ($ Billion)

- Sterling SIHI: Revenue Share, By Segment, 2023 (%)

- Sterling SIHI: Revenue Share, By Region, 2023 (%)

- Samson Pump: Net Sales, 2023-2033 ($ Billion)

- Samson Pump: Revenue Share, By Segment, 2023 (%)

- Samson Pump: Revenue Share, By Region, 2023 (%)

- Value Specializes: Net Sales, 2023-2033 ($ Billion)

- Value Specializes: Revenue Share, By Segment, 2023 (%)

- Value Specializes: Revenue Share, By Region, 2023 (%)

- Wenling Tingwei: Net Sales, 2023-2033 ($ Billion)

- Wenling Tingwei: Revenue Share, By Segment, 2023 (%)

- Wenling Tingwei: Revenue Share, By Region, 2023 (%)

Infinitive Data Research provides comprehensive market research, offering in-depth market analysis to help companies understand their target market and industry competition. This research predicts the market acceptance of your brand and products, ensuring informed decision-making for business success.

Competitor Analysis in the Chemical Industry Vacuum Pump Industry

Conducting a competitor analysis involves identifying competitors within the Chemical Industry Vacuum Pump industry and studying their various marketing strategies. This comparative data allows you to assess your company's strengths and weaknesses relative to competitors, providing insights to enhance your market position.

Importance of Continuous Market Research

Consistently conducting market research is essential for minimizing risk at every stage of business operations. Chemical Industry Vacuum Pump market research enables you to collect qualitative and quantitative data, which, when properly analyzed, leads to wise decisions that align with user and customer needs. Below are some crucial lessons learned through the Chemical Industry Vacuum Pump market research process:

Key Dimensions of Chemical Industry Vacuum Pump Market Analysis

- Trend and Pattern Identification: Analyzing data to spot market trends and patterns.

- Pricing Analysis: Assessing keyword pricing strategies.

- Actionable Insights: Implementing insights derived from data analysis.

- Market Potential: Evaluating the potential of the Chemical Industry Vacuum Pump market.

- Competitor Analysis: Studying competitors' strategies and performance.

- Location Analysis: Assessing optimal locations for market penetration.

- Distribution Channels Analysis: Evaluating the effectiveness of distribution channels.

- Market Size and Growth Rate: Measuring market size and growth potential.

- Market Profitability: Assessing profitability prospects.

- Key Success Factors: Identifying critical factors for success.

- Cost Structure: Understanding the cost structure within the Chemical Industry Vacuum Pump industry.

Target Audience for the Report

This report is valuable for a diverse audience, including:

- Chemical Industry Vacuum Pump Market Manufacturers: To understand market dynamics and enhance production strategies.

- Investors and Financing Companies: To assess investment opportunities and risks.

- Chemical Industry Vacuum Pump Market Suppliers: To identify market demands and supply chain efficiencies.

Necessity of the Report

Making Crucial Business Decisions

Understanding the Chemical Industry Vacuum Pump market, competition, and industry landscape is vital for making informed business decisions. Without current and relevant market research, decisions may be based on outdated or irrelevant information, potentially harming the business.

Securing Investment Funds

Attracting investors requires demonstrating thorough market research. Investors need assurance that you understand the sector, current and potential competition, and whether your idea addresses a market need.

Identifying New Business Opportunities

Chemical Industry Vacuum Pump market research goes beyond understanding trends and consumer behavior. It identifies new revenue streams and opportunities for business pivots. These insights can lead to strategic changes in the business model, promoting growth and adapting to market challenges.

Avoiding Business Failures

Market research also plays a crucial role in risk mitigation. It can reveal when not to pursue certain actions, saving the company from potential losses in revenue, brand image, and more. This proactive approach is often overlooked but is essential for long-term success.

Conclusion

Infinitive Data Research's comprehensive Chemical Industry Vacuum Pump market research provides critical insights for making solid business decisions, securing investments, identifying new opportunities, and avoiding potential failures. Understanding market dynamics through continuous research ensures your company remains competitive and thrives in the Chemical Industry Vacuum Pump industry.